Description

Polymethyl Methacrylate (PMMA): The Versatile Plastic You Know as Acrylic

Polymethyl Methacrylate, often referred to as PMMA or acrylic, is a ubiquitous synthetic polymer with a dazzling array of applications. From everyday objects like eyeglasses and aquariums to more specialized uses in medicine and automotive manufacturing, PMMA’s unique blend of properties makes it a highly sought-after material.

What is PMMA?

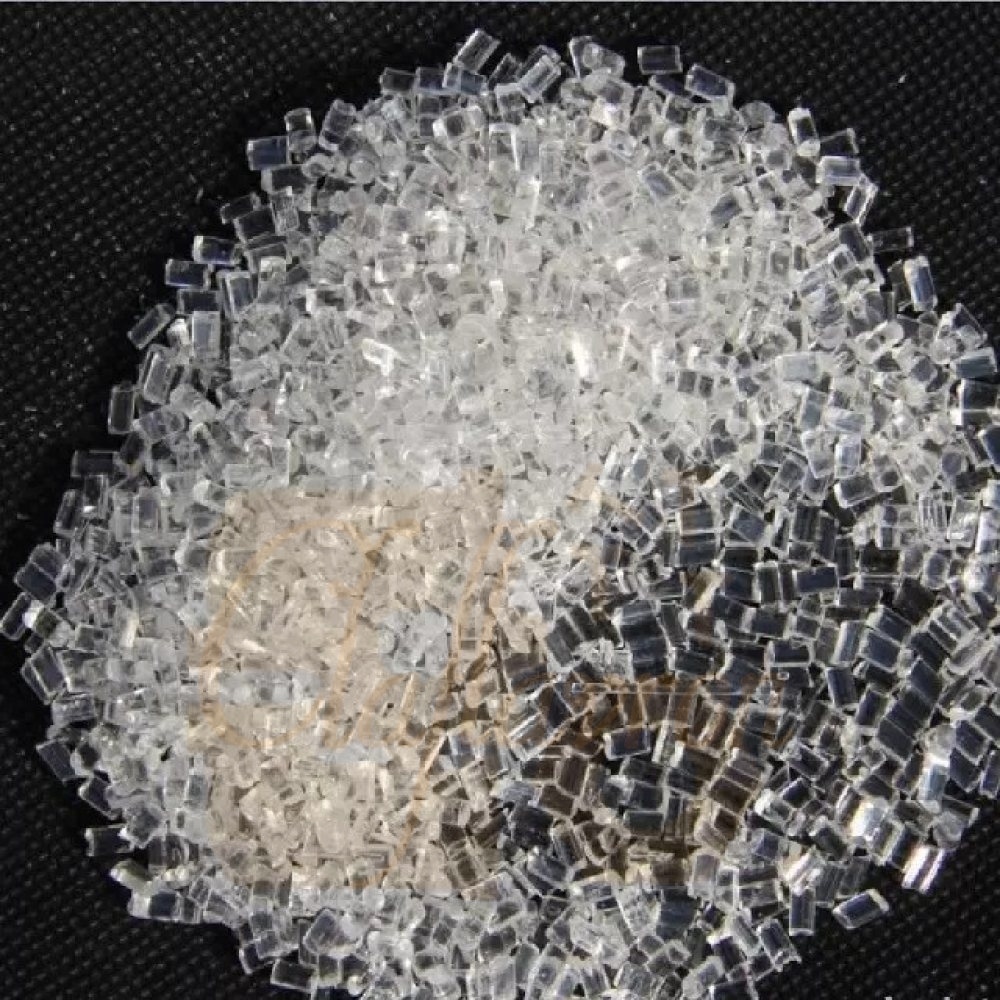

PMMA is a transparent thermoplastic, meaning it can be repeatedly softened by heating and hardened by cooling. It’s produced through the polymerization of methyl methacrylate monomers. This process results in a strong, lightweight, and shatter-resistant material known for its clarity, versatility, and ease of processing.

Key Properties and Benefits of PMMA:

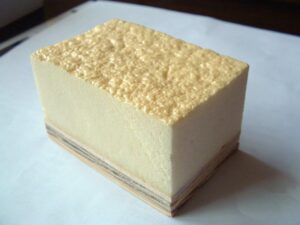

- Exceptional Transparency: PMMA boasts excellent optical clarity, allowing nearly 92% of visible light to pass through. This makes it ideal for applications requiring transparency, such as windows, lenses, and display screens. In fact, PMMA offers better light transmission than many types of glass.

- High Impact Resistance: While not completely unbreakable, PMMA is significantly more shatter-resistant than glass. This makes it a safer and more durable alternative in many applications.

- Weather Resistance: PMMA exhibits excellent resistance to weathering and degradation from prolonged exposure to sunlight, rain, and temperature fluctuations. This makes it suitable for outdoor applications like signage, skylights, and automotive parts.

- Lightweight: PMMA is significantly lighter than glass, making it easier to handle and transport. This is particularly beneficial in applications where weight is a concern, such as aircraft windows.

- Easy to Mold and Fabricate: PMMA can be easily molded, cut, drilled, and polished, making it a versatile material for a wide range of manufacturing processes. It can be formed into complex shapes using techniques like injection molding, thermoforming, and extrusion.

- Chemical Resistance: PMMA is resistant to many chemicals, including alkalis, dilute acids, and aliphatic hydrocarbons. However, it can be affected by strong solvents and concentrated acids.

- UV Resistance: PMMA exhibits good resistance to ultraviolet (UV) radiation, which can cause yellowing and degradation in other plastics. This makes it suitable for outdoor applications where UV exposure is a concern.

- Optical Properties: Beyond its transparency, PMMA can be modified to achieve specific optical properties, such as light diffusion, color filtration, and polarization.

Applications of PMMA:

The unique properties of PMMA have led to its widespread use in various industries. Here are some notable examples:

- Construction: Windows, skylights, roofing panels, bathroom fixtures, and signage.

- Automotive: Tail lights, instrument panels, lenses, and interior trim.

- Aerospace: Aircraft windows, cockpit canopies, and interior components.

- Medical: Bone cement, dentures, contact lenses, and medical implants.

- Electronics: LCD screens, light guides, and optical fibers.

- Consumer Goods: Eyeglasses, picture frames, aquariums, and furniture.

- Signage and Displays: Outdoor signage, point-of-sale displays, and illuminated signs.

- Art and Design: Sculptures, furniture, and display cases.

Advantages and Disadvantages:

Advantages:

- High transparency and clarity

- Impact resistance

- Weather resistance

- Lightweight

- Easy to mold and fabricate

- Chemical resistance

- UV resistance

Disadvantages:

- Can be scratched easily

- Susceptible to damage from strong solvents

- Higher cost compared to some other plastics

Environmental Considerations:

While PMMA is recyclable, the recycling infrastructure for acrylic is not as well-developed as it is for other commonly recycled plastics. Researchers are actively exploring ways to improve the recyclability of PMMA and develop more sustainable production methods.

Conclusion:

Polymethyl Methacrylate (PMMA) is a remarkable material that has revolutionized various industries with its exceptional properties. From everyday objects to highly specialized applications, PMMA’s versatility, transparency, and durability make it a vital component of modern life. As research and development continue, PMMA is poised to play an even greater role in shaping the future of materials science and engineering.

Reviews

There are no reviews yet.