Description

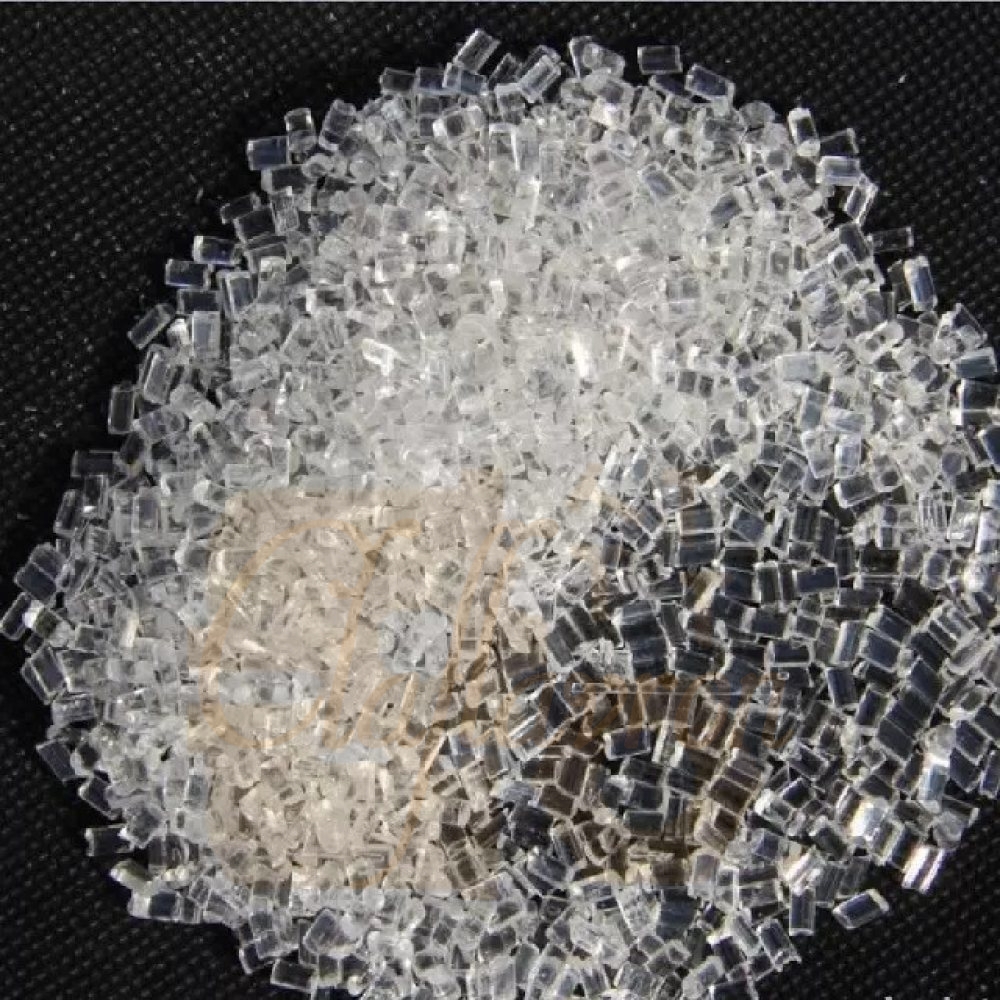

Polymethyl Methacrylate (PMMA): A Crystal-Clear Look at Acrylic

Polymethyl Methacrylate, more commonly known as PMMA or acrylic, is a versatile synthetic polymer that finds applications in a wide array of industries. From the windshields of aircraft to the protective screens around hockey rinks, PMMA’s unique properties and ease of manufacturing have made it a staple material in modern life.

What is PMMA?

PMMA is a thermoplastic polymer derived from the polymerization of methyl methacrylate. This process creates long chains of repeating methyl methacrylate units, resulting in a material that is strong, lightweight, and highly transparent. Its clarity is often compared to glass, making it an attractive alternative in many applications.

Key Properties of PMMA:

- Exceptional Transparency: PMMA boasts excellent light transmission, exceeding that of many types of glass. This clarity makes it ideal for applications where visibility is paramount.

- Lightweight: Compared to glass, PMMA is significantly lighter, which can be a crucial advantage in weight-sensitive applications like aircraft windows.

- Impact Resistance: While not as robust as polycarbonate, PMMA offers good impact resistance, surpassing that of glass.

- Weather Resistance: PMMA is renowned for its ability to withstand prolonged exposure to sunlight, rain, and extreme temperatures without significant degradation. It resists yellowing and clouding, making it suitable for outdoor applications.

- Ease of Fabrication: PMMA can be easily molded, cut, drilled, and polished. This versatility allows for the creation of a wide range of shapes and designs.

- Chemical Resistance: PMMA is resistant to many chemicals, although it can be susceptible to certain solvents and alkalis.

- Good Electrical Insulation: PMMA is a good electrical insulator, making it useful in electronic applications.

Applications of PMMA:

The versatile properties of PMMA have led to its widespread use in various industries:

- Construction: Windows, skylights, signage, displays, and decorative panels. Its weather resistance and transparency make it a popular choice for outdoor applications.

- Automotive: Tail lights, instrument panels, and interior trim. Its impact resistance and aesthetic appeal are valued in automotive design.

- Aerospace: Aircraft windows, canopies, and interior components. Its lightweight and high transparency are crucial for aircraft performance and safety.

- Medical: Bone cement, dentures, and contact lenses. Its biocompatibility and ease of sterilization make it suitable for medical applications.

- Electronics: Displays for mobile phones, televisions, and other electronic devices. Its clarity and ability to be molded into complex shapes are essential for modern electronics.

- Art and Design: Sculptures, jewelry, and furniture. Its transparency and ability to be colored make it a popular material for artists and designers.

- Lighting: Light guides, lenses, and diffusers. Its excellent light transmission properties are critical for effective lighting systems.

- Protective Barriers: Hockey rink shields, safety screens, and sneeze guards. Its impact resistance and transparency provide protection without compromising visibility.

Advantages of PMMA over Glass:

In many applications, PMMA offers several advantages over glass:

- Lighter Weight: Reduces overall weight, which can be critical in certain applications.

- Higher Impact Resistance: Less prone to shattering, enhancing safety.

- Greater Design Flexibility: Easier to mold and shape into complex designs.

- Improved UV Resistance: Less susceptible to degradation from sunlight.

Disadvantages of PMMA:

- Lower Scratch Resistance: More prone to scratches than glass.

- Susceptibility to Certain Chemicals: Can be damaged by certain solvents and alkalis.

- Lower Heat Resistance: Not suited for high-temperature applications.

- Can Be More Expensive than Glass: Depending on the application and specific requirements.

Environmental Considerations:

PMMA is recyclable, although recycling infrastructure for PMMA is not as widespread as for other plastics. Furthermore, research is ongoing to develop bio-based PMMA alternatives derived from renewable sources, aiming to improve its environmental footprint.

Conclusion:

Polymethyl Methacrylate (PMMA) is a highly versatile and valuable material with a wide range of applications. Its exceptional transparency, lightweight nature, and ease of fabrication make it a compelling alternative to glass in many situations. As technology advances and sustainability concerns grow, ongoing research and development are likely to further enhance the properties and applications of this remarkable polymer. From the everyday objects we use to the advanced technologies that shape our world, PMMA continues to play a significant role in modern life.

Reviews

There are no reviews yet.