Description

The Power of PEBA: Why This High-Performance Elastomer is Changing the Game

If you’ve recently slipped on a pair of high-end marathon running shoes or watched a medical documentary featuring advanced heart catheters, you’ve likely encountered Polyether Block Amide, commonly known as PEBA.

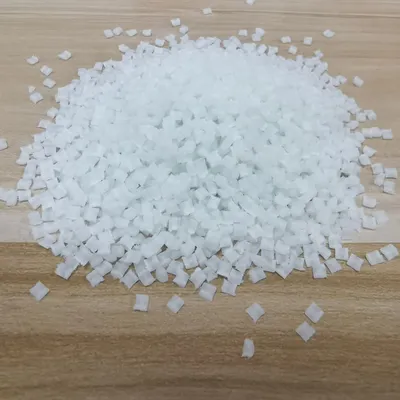

While it might not be a household name like “nylon” or “polyester,” PEBA is one of the most versatile and high-performing materials in the world of engineering. Often recognized by trade names like Pebax® (Arkema) or Vestamid® E (Evonik), this thermoplastic elastomer (TPE) bridges the gap between rigid plastics and flexible rubbers.

But what exactly makes PEBA so special? Let’s dive into the science, the benefits, and the real-world applications of this “super-polymer.”

The Science: A Best-of-Both-Worlds Material

PEBA is a block copolymer. To understand what that means, imagine a chain made of two different types of links:

- Hard Segments (Polyamide/Nylon): These provide the material’s strength, heat resistance, and chemical durability.

- Soft Segments (Polyether): These provide the flexibility, elasticity, and “bounce.”

By adjusting the ratio of these two segments, manufacturers can create a PEBA that is as soft as an eraser or as rigid as a plastic ruler. This “tunability” is why PEBA is favored across so many different industries.

Key Properties That Set PEBA Apart

Why do engineers choose PEBA over traditional rubbers or other elastomers? It comes down to four standout characteristics:

1. Incredible Energy Return

In the world of sports, PEBA is famous for its “spring.” It has a very low energy loss (hysteresis). When you deform the material, it snaps back to its original shape with minimal energy lost as heat. This provides the “propulsion” felt in modern super-shoes.

2. Extreme Lightweight

PEBA is significantly lighter than other thermoplastic elastomers. In industries where every gram counts—like aerospace or professional athletics—PEBA provides high performance without the bulk.

3. Low-Temperature Toughness

Many plastics become brittle and crack when they get cold. PEBA maintains its flexibility and impact resistance even in sub-zero temperatures, making it the gold standard for winter sports gear.

4. Chemical and Fatigue Resistance

PEBA can withstand constant bending and stretching (flex fatigue) millions of times without breaking. It also stands up well to oils, greases, and various chemicals.

Where Do We Use PEBA?

1. High-Performance Footwear

If you look at the midsoles of the shoes used to break marathon records, you’ll find PEBA foam. It provides the perfect combination of cushioning and energy return, allowing athletes to run faster with less muscle fatigue. It’s also used in the “plates” and outsoles of soccer cleats and track spikes.

2. Medical Devices

In the medical field, PEBA is a lifesaver. Because it is biocompatible and can be extruded into very thin, precise tubes, it is the primary material for catheters. Its ability to be “stiff” at the handle end while remaining “soft and flexible” at the tip allows surgeons to navigate through delicate blood vessels without causing damage.

3. Winter Sports

From ski boots to high-altitude climbing gear, PEBA is used because it doesn’t stiffen up in the snow. A ski boot made with PEBA will feel the same at -10°C as it does in the shop, ensuring consistent performance for the skier.

4. Industrial Applications

Because of its durability and silent operation, PEBA is used in silent gears, conveyor belts, and specialized gaskets in automotive and aerospace engineering.

The Green Factor: Bio-Based PEBA

The manufacturing world is pushing for sustainability, and PEBA is leading the way. Many versions of PEBA (such as Pebax® Rnew) are derived from castor beans. This bio-based origin reduces the carbon footprint of the material without sacrificing any of its high-performance properties. For brands looking to go green without losing quality, “castor-to-catheter” or “bean-to-boot” is a compelling story.

Conclusion

Polyether Block Amide (PEBA) is a masterclass in materials science. It proves that you don’t have to choose between strength and flexibility, or performance and sustainability. Whether it’s helping a patient recover from surgery or helping a runner shave seconds off their personal best, PEBA is the silent engine behind many of today’s greatest technological leaps.

Next time you lace up your sneakers or hit the ski slopes, take a moment to appreciate the chemistry beneath your feet!

Are you an engineer or designer considering PEBA for your next project? Or a consumer amazed by the tech in your gear? Let us know your thoughts in the comments below!

Reviews

There are no reviews yet.