Description

Beyond the Bakelite Revolution: Understanding the Enduring Power of Phenol Formaldehyde Resin

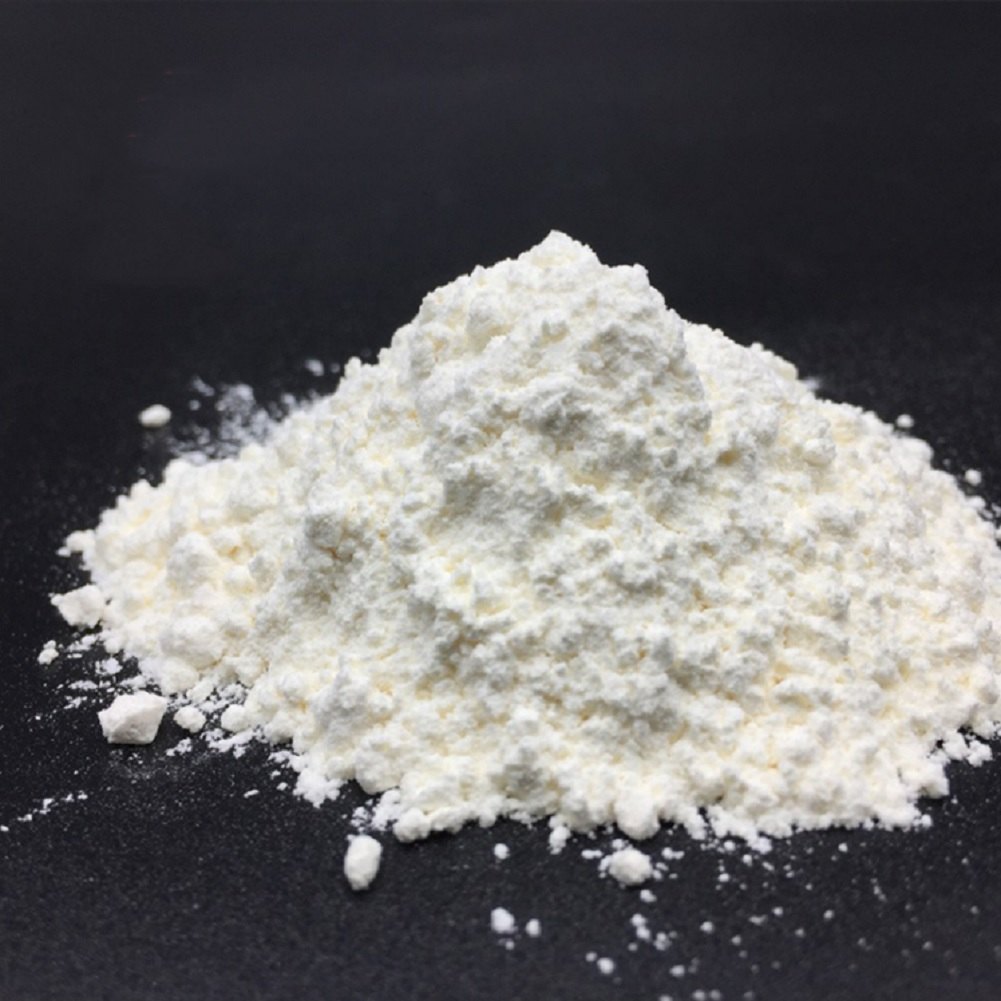

We often hear about the “plastic age” and the subsequent rise of polymers that have transformed our world. But long before the sleek, brightly colored plastics we know and love, there was a true pioneer: Phenol Formaldehyde Resin. This remarkable material, often known by its brand name Bakelite, wasn’t just a predecessor; it was a revolution that paved the way for virtually every synthetic polymer that followed.

So, what exactly is this foundational polymer, and why does it continue to hold relevance even in our modern, high-tech material landscape? Let’s dive in.

The Birth of a Synthetic Wonder

Imagine a world where electrical insulation was unreliable, where durable, heat-resistant components were scarce, and where the aesthetics of everyday objects were largely dictated by natural materials. This was the reality before Dr. Leo Baekeland, a Belgian-born chemist, stumbled upon a serendipitous discovery in the early 1900s.

Through a series of reactions involving phenol (a component derived from coal tar) and formaldehyde (a simple organic compound), Baekeland created a novel synthetic resin. This material, when heated, could be molded into virtually any shape and, upon cooling, hardened into an incredibly robust and stable substance. He named this groundbreaking invention Bakelite, a name that would soon become synonymous with innovation.

What Makes Phenol Formaldehyde Resin So Special?

The magic of phenol formaldehyde resin lies in its unique chemical structure and the resulting properties:

- Exceptional Heat Resistance: Unlike many early plastics that would melt or deform under heat, Bakelite could withstand significant temperatures, making it ideal for electrical components, cookware handles, and automotive parts.

- Excellent Electrical Insulation: This was a game-changer for the burgeoning electrical industry. Bakelite’s non-conductive nature made it perfect for switches, outlets, and other components that needed to safely manage electricity.

- High Strength and Rigidity: Phenol formaldehyde resin is a thermosetting plastic, meaning once it’s cured, it cannot be remelted or reshaped. This imparts incredible strength and stiffness, making it suitable for demanding applications.

- Chemical Resistance: It exhibits good resistance to a range of chemicals, adding to its durability and longevity.

- Good Machinability: Once cured, it can be drilled, milled, and otherwise shaped, allowing for precise component manufacturing.

- Aesthetic Versatility: While initially known for its deep brown or black color, variations and additives allowed for a range of colors, and its glossy finish gave objects a premium feel.

From Radios to Rolls-Royce: The Early Impact

The impact of Bakelite was immediate and profound. It quickly found its way into:

- Electrical Appliances: From early radios and telephones to light fixtures and vacuum cleaner housings, Bakelite was the material of choice for its insulating and durable properties.

- Automotive Industry: Engine components, distributor caps, and even interior trim benefited from its heat and oil resistance.

- Household Goods: Think of the iconic ashtrays, camera bodies, and jewelry made from Bakelite. Its durability and unique aesthetic made these objects highly desirable.

- Industrial Applications: Its strength and stability made it indispensable in various manufacturing processes.

The Enduring Legacy and Modern Relevance

While newer, more versatile plastics have emerged, phenol formaldehyde resin hasn’t disappeared. Its unique combination of properties still makes it a preferred material in specific applications:

- High-Performance Brake Pads: Its heat resistance and friction properties are crucial for the demanding environment of braking systems.

- Laminates: Phenol formaldehyde resin is a key component in decorative and industrial laminates, used for countertops, circuit boards, and high-pressure laminates (HPL) for furniture and wall panels.

- Adhesives and Coatings: Its strong bonding capabilities make it valuable in certain adhesive formulations and protective coatings.

- Foundry Resins: It’s used as a binder in sand casting molds and cores, thanks to its strength and thermal stability.

- Insulation Materials: In some specialized applications, its excellent electrical and thermal insulation properties are still leveraged.

A Testament to Material Science

Phenol formaldehyde resin stands as a testament to the power of material science and the ingenuity of early chemists. It wasn’t just a material; it was a catalyst for innovation, ushering in an era of synthetic materials that would fundamentally change how we live, work, and interact with the world around us.

So, the next time you encounter a vintage radio, a sturdy laminate countertop, or even the robust brake pads in your car, take a moment to appreciate the enduring legacy of phenol formaldehyde resin – the material that started it all.

What are your memories or experiences with Bakelite or phenol formaldehyde resin? Share them in the comments below!

Reviews

There are no reviews yet.