Description

The oil and gas industry is a critical component of the global energy sector, and it relies heavily on various types of equipment and materials to facilitate exploration, drilling, and production. One such essential component is Oil Country Tubular Goods (OCTG), which plays a vital role in the extraction of oil and gas from wellbores. This article aims to provide an in-depth understanding of OCTG, its components, types, and applications in the oil and gas industry.

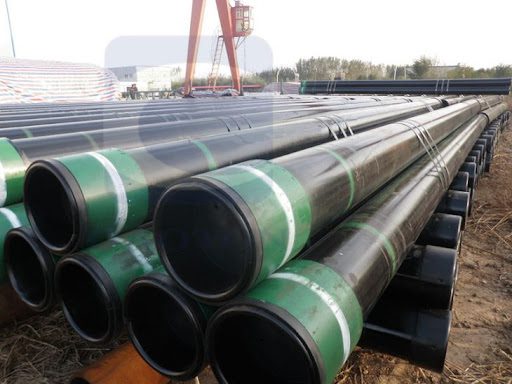

OCTG is a term that encompasses a variety of seamless and welded steel tubes used in the oil and gas industry for drilling, completing, and producing oil and gas wells. These tubular goods are designed to withstand the extreme conditions and pressures encountered in oil and gas wells, making them a critical component of the drilling process.

OCTG comprises three main components: drill pipe, casing, and tubing.

- Drill Pipe: Drill pipe is a heavy seamless steel pipe that connects the drilling rig to the drill bit. It is subject to torsional and axial loads during drilling operations and is designed to transmit these loads to the rig. Drill pipe comes in various sizes, weights, and grades, depending on the application and drilling conditions.

- Casing: Casing is a larger-diameter pipe that is installed in the wellbore after drilling to provide structural support and prevent the wellbore from collapsing. Casing also isolates different formations, preventing fluid communication between them. Casing comes in various sizes, weights, and grades, depending on the application and wellbore conditions.

- Tubing: Tubing is a smaller-diameter pipe that is installed inside the casing to transport oil and gas from the wellbore to the surface. Tubing also comes in various sizes, weights, and grades, depending on the application and wellbore conditions.

OCTG is further classified into two main categories based on the manufacturing process: seamless and welded.

- Seamless OCTG: Seamless OCTG is manufactured by piercing a solid billet of steel and then gradually reducing its diameter to the desired size. Seamless OCTG is generally stronger and more reliable than welded OCTG and is used in high-pressure and high-temperature applications.

- Welded OCTG: Welded OCTG is manufactured by welding two steel plates together to form a tube. Welded OCTG is generally less expensive than seamless OCTG and is used in low-pressure and low-temperature applications.

OCTG is also classified based on its application in the oil and gas well:

- Drilling OCTG: Drilling OCTG is used during the drilling phase of the well and includes drill pipe, heavyweight drill pipe, and drill collars.

- Production OCTG: Production OCTG is used during the production phase of the well and includes casing and tubing.

In conclusion, Oil Country Tubular Goods (OCTG) is a critical component of the oil and gas industry, providing the necessary structural support and fluid conveyance required for drilling, completing, and producing oil and gas wells. OCTG comes in various sizes, weights, and grades, depending on the application and wellbore conditions, and is further classified into seamless and welded categories based on the manufacturing process. Understanding the importance of OCTG and its components, types, and applications is crucial for anyone involved in the oil and gas industry.

Tolerance

Chemical compositions

Mechanical properties

| Types of steel tubes | Tolerance of Outer Diameter | Tolerance of Wall Thickness | |||||||||

| Cold-rolled tubes | Tube sizes(mm) | Tolerances(mm) | Tolerances(mm) | ||||||||

| <114.3 | ±0.79 | -12.5% | |||||||||

| ≥114.3 | -0.5%,+1% | ||||||||||

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

| Grade | Type | Total elongation under load (%) | Yield strength (min) | Yield strength (max) | Tensile strength min Mpa | Hardness Max (HRC) | Hardness Max (HBW) | ||||

| J55 | – | 0.5 | 379 | 552 | 517 | – | – | ||||

| K55 | – | 0.5 | 379 | 552 | 655 | – | – | ||||

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – | ||||

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – | ||||

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | ||||

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | ||||

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | ||||

| C90 | – | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ||||

| C95 | – | 0.5 | 655 | 758 | 724 | – | – | ||||

| T95 | – | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ||||

| P110 | – | 0.6 | 758 | 965 | 862 | – | – | ||||

| Q125 | All | 0.65 | 862 | 1034 | 931 | – | – | ||||

|

UAE

K-55,N80 13-3/8″, 68 ppf SMLS, BTC, R3 9-5/8″, 47 ppf SMLS, BTC, R3 9560 meters |

Nigeria

N80 9-5/8″ 47lb/ft R1 105000 feet(project) |

||||||||||

|

Jordan

H- 40 14″ O.D,45.61 Ib/ft, Range II, wt:0,312″ 2700 meters |

Vietnam

J55, 13 3/8″ #54.5 PPF, BTC, R3, 4000MTRS 9 5/8″, #36PPF, BTC, R3, 2000MTRS |

||||||||||

|

Oman

K55 10 3/4″, 40.5 PPF, 12 meters length, Qty 155 pcs 8 5/8″ K55 32 PPF, 12 meters length, Qty 270 pcs |

Irap

P110 9-7/8″, 62.8ppf Vam Top Thread Range3 14000 Feet 7″ 29ppf,+/-40ft,Vam Top Range 3 3000 Feet |

||||||||||

Reviews

There are no reviews yet.