Description

The Unsung Hero of Metal Fabrication: Understanding No. 1 Finish Sheets

In the world of metal fabrication, the final appearance of a product is often just as important as its functionality. While coatings, paint, and polishing get most of the attention, the foundation of a visually appealing and durable product often lies in the choice of the right base material, specifically the finish of the metal sheet itself. Among the many finishes available, the No. 1 Finish stands out as a workhorse, a foundational surface that often gets overlooked but plays a crucial role in a wide range of applications.

So, what exactly is a No. 1 Finish and why is it important?

Defining the No. 1 Finish:

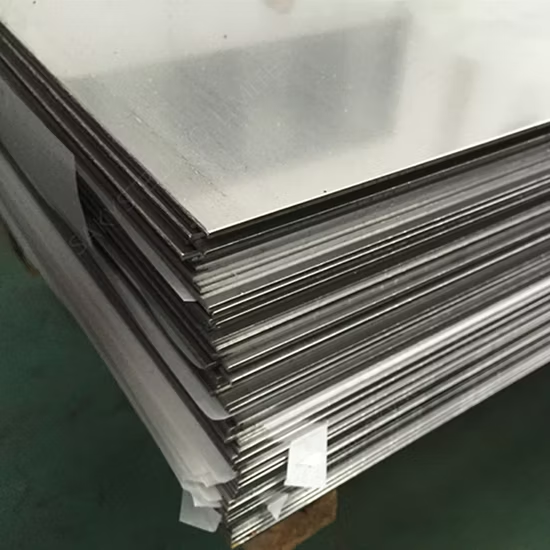

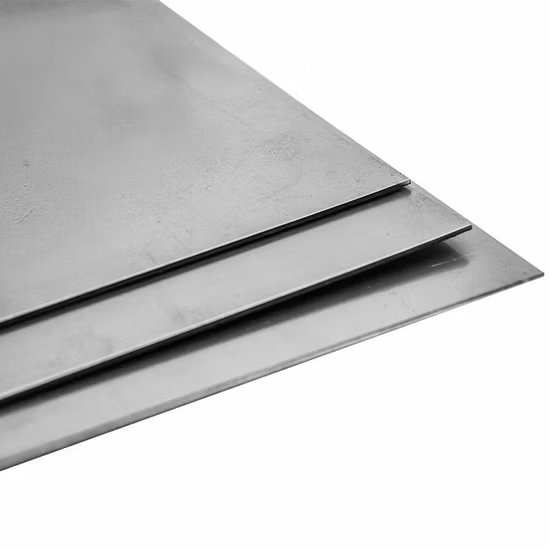

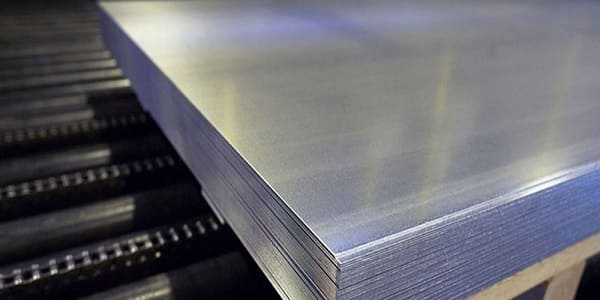

A No. 1 finish is a hot-rolled, annealed, and descaled finish on stainless steel and other metals. It’s characterized by its dull, rough surface, often displaying a mottled appearance. This finish is produced by rolling the metal at high temperatures, followed by annealing to relieve internal stresses, and finally descaling to remove any surface oxides.

Key Characteristics of No. 1 Finish Sheets:

- Rough Surface: This is the defining characteristic. The surface is not smooth or reflective.

- Dull Appearance: Compared to polished or bright annealed finishes, No. 1 has a muted, non-reflective appearance.

- Scale Removal: While descaling aims to remove surface oxides, slight imperfections and variations in the surface texture are common.

- Good Formability: The annealing process typically results in a softer and more ductile material, making it well-suited for forming and bending operations.

- Cost-Effective: No. 1 finish is generally one of the more economical finishes available, making it a practical choice for many applications.

Why Choose a No. 1 Finish?

While its lack of visual appeal might seem like a drawback, the No. 1 finish offers a range of compelling advantages:

- Excellent Base for Coatings: The rough surface provides an ideal key for paints, powder coatings, and other finishes to adhere, resulting in a stronger and more durable coating.

- Superior for Heavy-Duty Applications: In situations where aesthetic appeal is secondary to functionality and durability, No. 1 finish is a strong contender. Its robust surface provides inherent resistance to wear and tear.

- Cost-Effectiveness for Functional Components: When the final product will be hidden or masked, using a No. 1 finish can significantly reduce material costs without compromising performance.

- Facilitates Subsequent Processing: The annealed and descaled surface allows for easier welding, fabrication, and machining compared to materials with heavy scale or surface impurities.

Applications Where No. 1 Finish Shines:

No. 1 finish sheets find their niche in a diverse range of industries and applications, including:

- Heavy Industrial Equipment: Tanks, pressure vessels, and structural components in industries like chemical processing, food processing, and pharmaceuticals.

- Automotive Components: Interior panels, reinforcements, and other parts that are not directly visible but require good formability and corrosion resistance.

- Appliances: Internal components, frames, and supports that are hidden from view.

- Construction: Structural elements, cladding substrates, and roofing components where a durable and cost-effective material is needed.

- Agricultural Equipment: Machinery components that need to withstand harsh environments.

Beyond the Basics: Considerations for Choosing No. 1 Finish:

While No. 1 finish offers numerous advantages, it’s essential to consider specific project requirements. Factors like:

- Corrosion Resistance: While stainless steel inherently offers corrosion resistance, specific alloy grades should be chosen based on the intended environment.

- Surface Cleanliness: Ensure the material is adequately descaled to prevent issues with coating adhesion or contamination.

- Forming Requirements: Verify the material meets the required ductility and formability for the intended fabrication processes.

Conclusion:

The No. 1 finish sheet may not be the flashiest material, but its practicality, durability, and cost-effectiveness make it a vital component in countless applications. By understanding its characteristics and benefits, designers and engineers can leverage this unsung hero of metal fabrication to create strong, functional, and cost-efficient products for a wide range of industries. So, next time you’re specifying metal for a project, don’t overlook the humble yet powerful No. 1 finish. It might just be the perfect foundation you need.

Reviews

There are no reviews yet.