Description

Niobium Catalysts: A Powerful Tool for Chemical Transformations

Niobium, a transition metal known for its high melting point and corrosion resistance, is increasingly making waves in the field of catalysis. Niobium-based catalysts are proving to be versatile and effective for a wide range of chemical reactions, offering advantages like robustness, reusability, and environmental friendliness. This article delves into the intriguing world of niobium catalysts, exploring their properties, applications, and the reasons behind their rising popularity.

Why Niobium? The Allure of Niobium-Based Catalysts

The effectiveness of niobium as a catalytic material stems from its unique electronic structure and its ability to form various oxides and mixed oxides. Here’s why niobium is gaining prominence:

- Lewis Acidity: Niobium exhibits Lewis acidity, allowing it to activate various substrates by interacting with electron-rich centers. This is particularly useful in reactions like esterifications, transesterifications, and Friedel-Crafts acylations.

- Redox Properties: Niobium can exist in multiple oxidation states (typically +3, +4, and +5), facilitating redox reactions such as oxidation and reduction. These oxidation states allow it to accept and donate electrons, a crucial aspect of catalysis.

- High Thermal Stability: Niobium oxides possess high thermal stability, enabling their use in high-temperature reactions where other catalysts might decompose or lose activity.

- Acidic and Basic Properties: Depending on the preparation method and composition, niobium-based catalysts can exhibit both acidic and basic properties, expanding their applicability to a wider range of reactions.

- Environmental Friendliness: Niobium is considered a relatively benign metal compared to some other transition metals used in catalysis, contributing to the development of more sustainable chemical processes.

A Spectrum of Applications: Where Niobium Catalysts Shine

The versatility of niobium catalysts is reflected in the diverse range of chemical reactions they can facilitate. Some key applications include:

- Esterification and Transesterification: Niobium catalysts are highly effective in producing esters from carboxylic acids and alcohols, and in transesterifying triglycerides for biodiesel production. Their robust nature allows for repeated use without significant loss of activity.

- Oxidation Reactions: Niobium oxides are frequently used as components in catalysts for selective oxidation reactions, playing a role in converting hydrocarbons to valuable chemicals like aldehydes and ketones.

- Dehydration and Hydration Reactions: Niobium phosphates and niobic acid have shown excellent catalytic activity in dehydration reactions, such as the conversion of alcohols to alkenes, and in hydration reactions, such as the addition of water to alkenes.

- Alkylation and Acylation Reactions: Niobium catalysts can promote alkylation reactions, where alkyl groups are added to molecules, and acylation reactions, where acyl groups are added. These reactions are fundamental in the synthesis of numerous organic compounds.

- Polymerization Reactions: Niobium complexes can be used as catalysts in polymerization reactions, leading to the formation of polymers with tailored properties.

Types of Niobium Catalysts: Tailoring the Catalyst to the Task

The properties of niobium catalysts can be finely tuned by modifying their chemical composition and physical structure. Common types of niobium catalysts include:

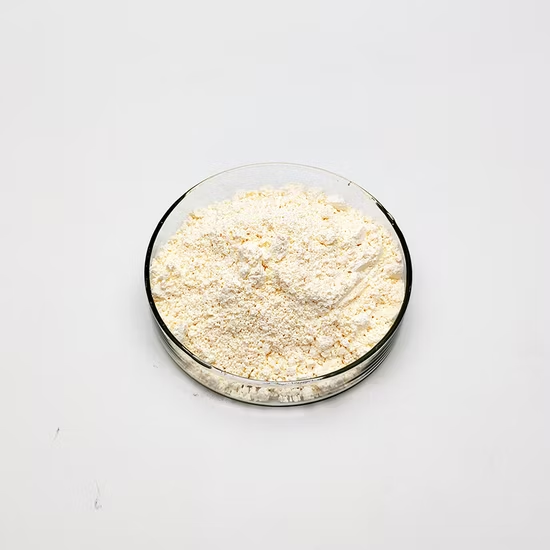

- Niobium Oxides (Nb2O5): This is the most common form of niobium catalyst, often used as a support material or a catalyst in its own right.

- Niobic Acid (Nb2O5·nH2O): A hydrated form of niobium oxide, niobic acid exhibits strong Brønsted acidity, making it suitable for acid-catalyzed reactions.

- Mixed Oxides: Combining niobium oxide with other metal oxides (e.g., TiO2, ZrO2, SiO2) can enhance catalytic performance by modifying the electronic and structural properties.

- Niobium Phosphates: These materials exhibit both acidic and redox properties, making them useful in various catalytic applications.

- Supported Niobium Catalysts: Niobium can be deposited on high surface area supports like silica or alumina to improve its dispersion and accessibility, leading to enhanced catalytic activity.

The Future is Bright: Opportunities and Challenges

Niobium catalysts are poised to play an increasingly significant role in the future of chemical synthesis. Ongoing research is focused on:

- Improving Catalyst Activity: Enhancing the activity and selectivity of niobium catalysts through modifications in composition and structure.

- Developing Novel Catalyst Designs: Exploring new catalyst architectures, such as single-atom catalysts and nanocatalysts, to maximize the utilization of niobium.

- Expanding Applications: Discovering new applications for niobium catalysts in areas like biomass conversion, CO2 reduction, and environmental remediation.

While the potential of niobium catalysts is immense, challenges remain. These include optimizing the catalyst preparation methods, understanding the reaction mechanisms at the atomic level, and scaling up the production of niobium-based catalysts for industrial applications.

Conclusion:

Niobium catalysts are emerging as powerful tools for a wide range of chemical transformations. Their unique properties, versatility, and environmental friendliness make them an attractive alternative to traditional catalysts. As research and development continue, we can expect to see niobium catalysts playing an increasingly crucial role in driving innovation and sustainability in the chemical industry. The future of catalysis is undoubtedly intertwined with the continued exploration and application of this remarkable metal.

Reviews

There are no reviews yet.