Description

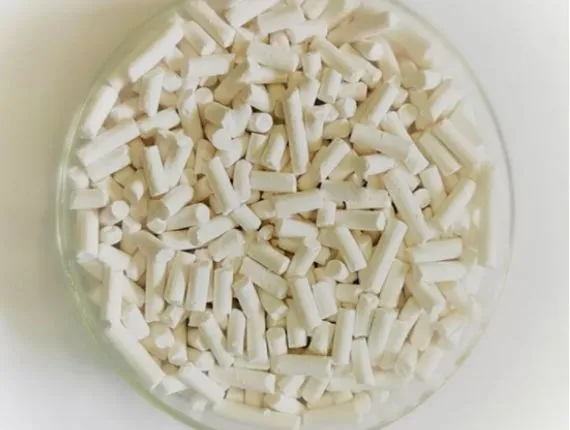

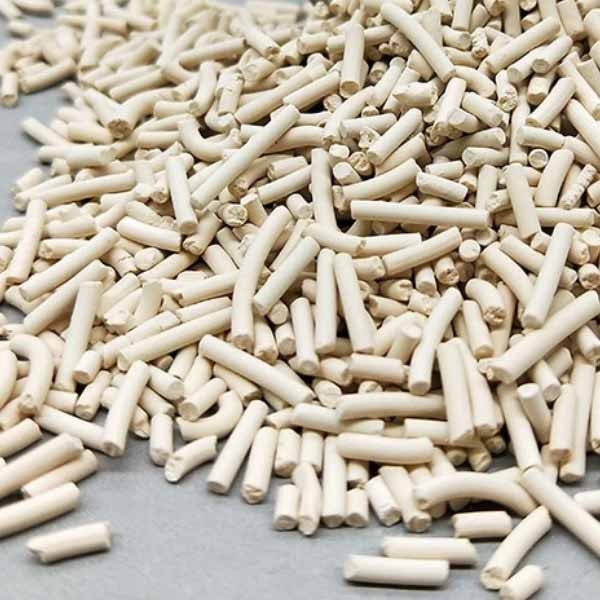

Molecular Sieve 13X Pellets: Versatile Workhorses in Gas and Liquid Separation

In the world of industrial separation and purification, molecular sieves have emerged as indispensable tools. Among these, Molecular Sieve 13X Pellets stand out for their exceptional versatility and performance in a wide array of applications. These synthetic zeolites, characterized by their large pore size and high adsorption capacity, play a crucial role in ensuring product quality, optimizing processes, and enhancing efficiency across diverse industries.

What are Molecular Sieve 13X Pellets?

Molecular Sieve 13X is a type of synthetic zeolite with a highly crystalline structure. This structure creates pores with a diameter of approximately 10 angstroms (1 nm), allowing it to selectively adsorb molecules based on their size and polarity. The “13X” designation indicates this pore size in angstroms. These pellets are typically composed of sodium aluminosilicate, giving them a strong affinity for water, carbon dioxide, hydrocarbons, and other polar molecules.

Key Properties and Advantages:

Several key properties contribute to the widespread use of 13X pellets:

- High Adsorption Capacity: The large pore size and high surface area of 13X pellets enable them to adsorb significant amounts of target molecules, even at low concentrations.

- Selective Adsorption: The uniform pore size allows for selective adsorption, separating molecules based on their size and shape.

- High Mechanical Strength: The pellets are engineered for durability and resistance to attrition, ensuring long-term performance in demanding industrial environments.

- Regenerability: Molecular Sieve 13X can be regenerated by heating the pellets under vacuum or purging them with a dry gas, making them a cost-effective solution for continuous operation.

- Chemical Stability: These pellets are generally stable in a wide range of operating conditions, making them suitable for various applications.

Applications Across Industries:

The versatile nature of Molecular Sieve 13X Pellets makes them invaluable across a multitude of industries, including:

- Air Separation: 13X sieves are frequently used in air separation plants to remove water, carbon dioxide, and hydrocarbons, ensuring the production of high-purity oxygen, nitrogen, and argon.

- Natural Gas Processing: They play a critical role in removing water and sulfur compounds from natural gas, preventing corrosion and pipeline blockages.

- Petrochemicals: Molecular Sieve 13X is used to purify petrochemical feedstocks, removing contaminants that can poison catalysts or affect product quality.

- Refrigerant Drying: They are employed in refrigerant drying systems to remove moisture, preventing the formation of ice crystals that can damage refrigeration equipment.

- Medical Oxygen Concentrators: In medical oxygen concentrators, 13X sieves are used to separate nitrogen from air, providing a concentrated oxygen supply for patients with respiratory problems.

- Ethanol Production: 13X pellets are used in the dehydration of ethanol to produce fuel-grade ethanol, removing water to meet stringent fuel specifications.

- Drying of Insulating Glass: They are utilized to remove moisture between the panes of insulating glass windows and doors, preventing condensation and improving energy efficiency.

Choosing the Right Molecular Sieve:

While Molecular Sieve 13X is a robust and versatile option, selecting the appropriate molecular sieve depends on the specific application and the target molecules being separated. Factors to consider include:

- Pore Size: Different molecular sieves have different pore sizes, dictating the size of molecules they can adsorb.

- Chemical Composition: The chemical composition of the zeolite framework influences its affinity for different molecules.

- Application Requirements: Specific process parameters, such as temperature, pressure, and flow rate, should be considered.

Conclusion:

Molecular Sieve 13X Pellets are a versatile and reliable solution for a wide range of gas and liquid separation applications. Their high adsorption capacity, selectivity, and regenerability make them a valuable tool for optimizing processes, ensuring product quality, and enhancing efficiency across diverse industries. As industries continue to demand higher purity and more efficient separation processes, Molecular Sieve 13X Pellets will undoubtedly remain a crucial component in the arsenal of purification technologies.

Reviews

There are no reviews yet.