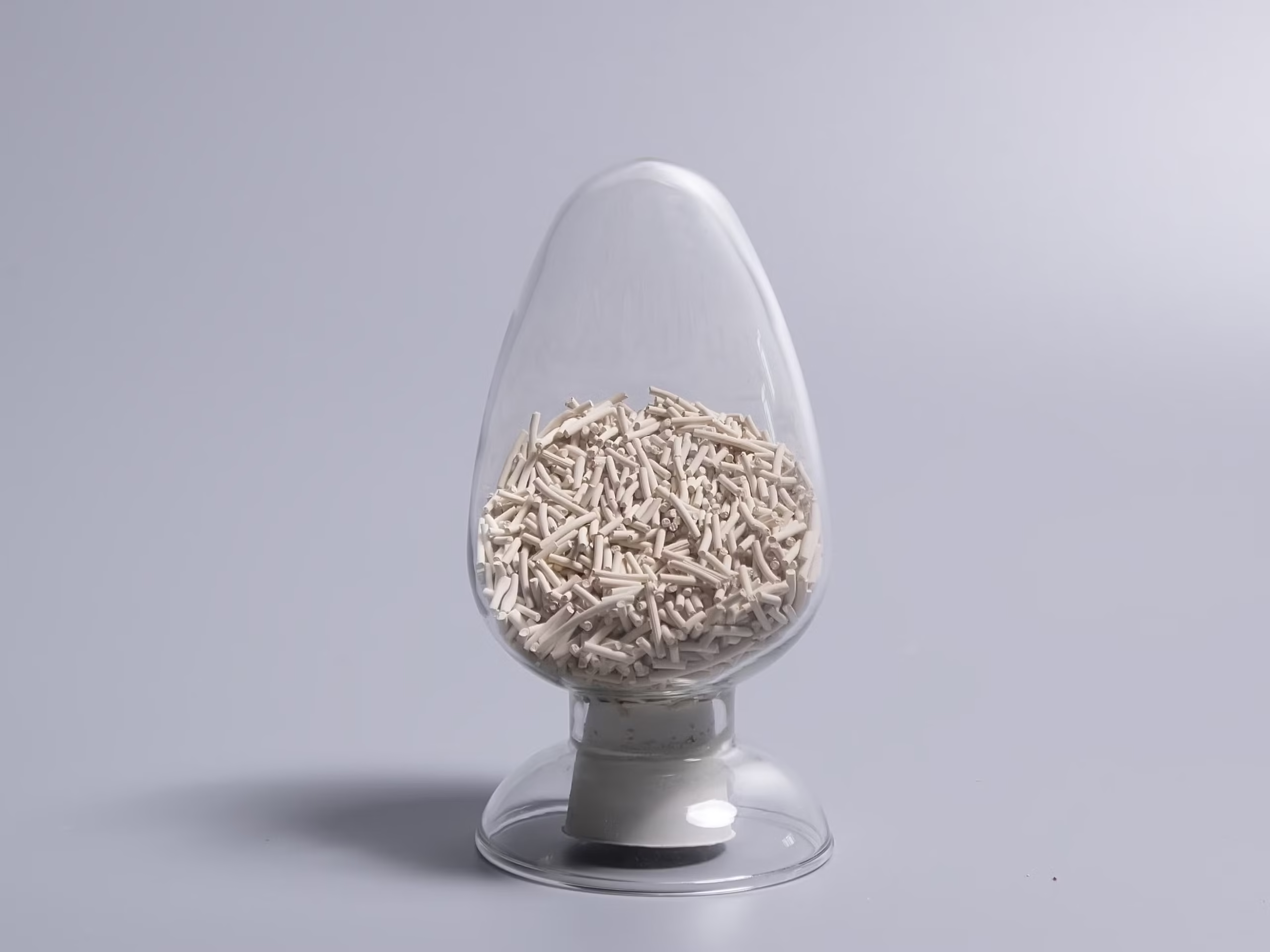

Description

Molecular Sieve 4A Pellets: Tiny Powerhouses for Precise Separation

In the world of chemical and industrial processing, precision is paramount. Whether it’s purifying gases, drying solvents, or selectively removing contaminants, the ability to manipulate molecules at a granular level is crucial. Enter Molecular Sieve 4A pellets: tiny, but incredibly powerful, agents of separation.

These seemingly unassuming pellets are far more sophisticated than they appear. They are synthetic aluminosilicate materials, a type of zeolite, characterized by a precisely defined pore size of 4 Angstroms (hence the “4A”). This meticulously controlled pore size acts like a molecular gatekeeper, allowing molecules smaller than 4 Angstroms to pass through and be adsorbed, while blocking larger molecules from entering. This selective adsorption capability is what makes Molecular Sieve 4A pellets so valuable in a wide range of applications.

Understanding the Magic: How Molecular Sieve 4A Works

The effectiveness of Molecular Sieve 4A lies in its unique structure. The crystalline lattice structure creates a network of interconnected pores. These pores are highly polar, having a strong affinity for polar molecules. The driving force behind adsorption is the strong electrostatic interaction between the sieve’s internal surface and the molecules that fit within its pores.

Think of it like a precisely sized strainer. Smaller particles (molecules) pass through, while larger ones are held back. The key is the precise size and polarity of the “strainer” – the 4 Angstrom pores and the polar environment within.

A Versatile Workhorse: Applications of Molecular Sieve 4A Pellets

The ability to selectively remove specific molecules makes Molecular Sieve 4A a versatile tool across various industries. Here are some key applications:

- Drying Gases: One of the most common uses is in drying gases, such as air, nitrogen, and hydrogen. Water molecules, being smaller than 4 Angstroms and highly polar, are readily adsorbed by the sieve, leaving behind a dry gas stream. This is crucial in industries requiring anhydrous environments, such as electronics manufacturing and pharmaceutical production.

- Drying Solvents: Similarly, Molecular Sieve 4A is used to dry organic solvents like ethanol, isopropanol, and toluene. This is vital in chemical synthesis, where even trace amounts of water can interfere with reactions.

- Air Separation: In some air separation processes, Molecular Sieve 4A can be used to selectively adsorb carbon dioxide and water vapor from air, allowing for the enrichment of oxygen or nitrogen.

- Static Drying of Packaging: Small packets of Molecular Sieve 4A are often found in packaged goods, such as electronics, pharmaceuticals, and diagnostic kits. These packets maintain a dry environment within the packaging, preventing moisture damage and extending shelf life.

- Ethanol Dehydration: Molecular Sieve 4A is extensively used in the production of fuel-grade ethanol. It selectively removes water from the ethanol-water mixture, resulting in highly concentrated ethanol suitable for use as a biofuel.

Advantages of Using Molecular Sieve 4A Pellets

Compared to other drying and separation methods, Molecular Sieve 4A offers several advantages:

- High Adsorption Capacity: They can adsorb a significant amount of target molecules relative to their weight.

- Selectivity: The precise pore size ensures that only specific molecules are adsorbed.

- Regeneration: The saturated sieve can be regenerated by heating it to remove the adsorbed molecules, allowing it to be reused multiple times. This makes it a cost-effective solution.

- Chemical Stability: They are generally chemically inert and stable under a wide range of conditions.

- Physical Durability: The pellet form provides good mechanical strength and resistance to attrition, ensuring long-term performance.

Considerations When Using Molecular Sieve 4A Pellets

While highly effective, there are a few considerations to keep in mind when using Molecular Sieve 4A:

- Pretreatment: Before use, the pellets typically need to be activated by heating to drive off any pre-adsorbed moisture.

- Operating Conditions: Temperature and pressure affect adsorption capacity. Optimal conditions should be determined for each application.

- Contamination: The presence of other molecules larger than 4 Angstroms can block the pores and reduce the effectiveness of the sieve.

- Dust Generation: The handling of pellets can sometimes generate dust, which may need to be controlled.

Conclusion

Molecular Sieve 4A pellets are indispensable tools in various industries requiring precise separation and purification. Their unique combination of pore size, polarity, and regenerability makes them a cost-effective and efficient solution for a wide range of applications. As technology advances and demands for purity become even more stringent, Molecular Sieve 4A pellets will continue to play a vital role in shaping the future of chemical processing.

Reviews

There are no reviews yet.