Description

Methacrylic Acid: A Versatile Building Block Shaping Modern Industries

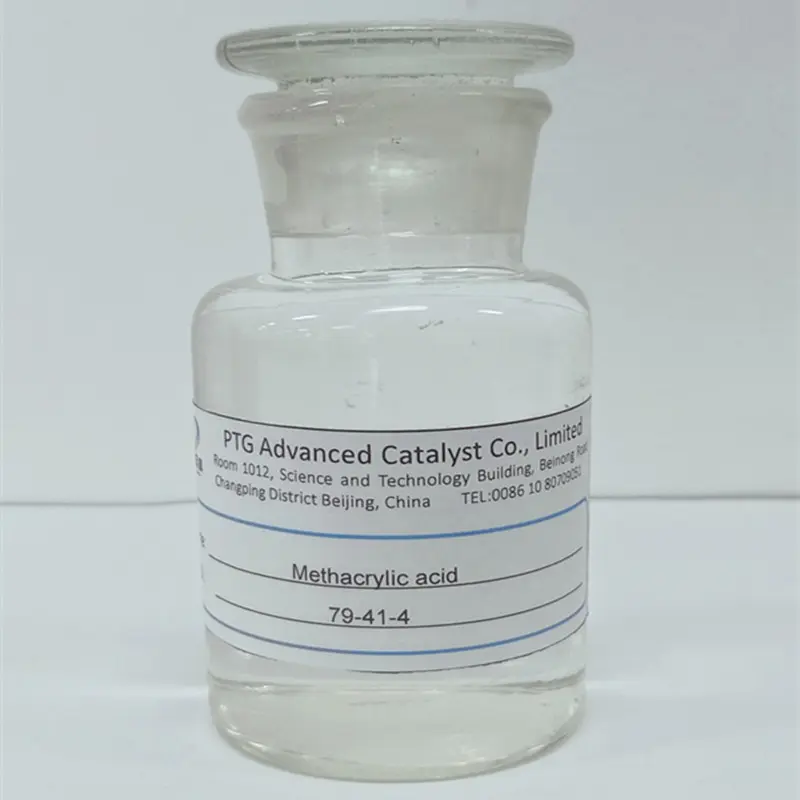

Methacrylic acid (MAA), a colorless, pungent-smelling organic acid, might not be a household name, but its influence is quietly shaping various aspects of modern life. This versatile chemical compound, with the molecular formula CH₂=C(CH₃)COOH, is primarily used as a monomer in the production of a wide range of polymers and resins, making it a crucial building block for numerous industries.

The Chemistry Behind its Power:

MAA’s reactivity stems from its unique molecular structure. The presence of both a vinyl group (CH₂=C) and a carboxylic acid group (COOH) allows it to undergo a variety of polymerization reactions. This enables the creation of homopolymers, where MAA is the sole repeating unit, as well as copolymers, where MAA is combined with other monomers to tailor specific material properties.

A Cornerstone of Polymer Production:

The primary application of MAA lies in the production of polymethacrylic acid (PMAA) and its esters, such as methyl methacrylate (MMA), which is then used to produce polymethyl methacrylate (PMMA), commonly known as acrylic or plexiglass. These materials are prized for their clarity, durability, and weather resistance, finding application in:

- Coatings and Adhesives: MAA-based polymers enhance the adhesion, durability, and gloss of paints, varnishes, and adhesives used in automotive, construction, and packaging industries.

- Plastics and Resins: From shatter-resistant windows and lenses to durable molded parts, MAA contributes to the creation of strong, transparent, and versatile plastics.

- Textiles: MAA polymers are used to improve the crease resistance, water repellency, and dye uptake of fabrics.

- Medical Applications: MAA-based hydrogels are biocompatible materials used in drug delivery systems, contact lenses, and wound dressings. Their ability to absorb water and swell makes them ideal for these applications.

- Superabsorbent Polymers (SAPs): MAA is a key component in the production of SAPs, which are widely used in disposable diapers, sanitary napkins, and agricultural applications for water retention.

Beyond Polymers: Emerging Applications:

While polymer production remains the dominant application, researchers are exploring novel uses for MAA, including:

- Corrosion Inhibitors: MAA and its derivatives can be used as corrosion inhibitors in various industrial processes.

- Enhanced Oil Recovery: MAA-based polymers are being investigated for their potential to improve the efficiency of oil extraction from underground reservoirs.

- Drug Delivery Systems: The pH-sensitivity of MAA-based polymers makes them attractive for targeted drug delivery, releasing medication specifically in desired areas of the body.

Production and Handling Considerations:

MAA is typically produced via the oxidation of isobutylene or tertiary butanol. The process requires careful control to ensure high yields and purity of the final product. Due to its corrosive and irritating nature, MAA requires proper handling and storage procedures to ensure worker safety and prevent environmental contamination.

Looking Ahead:

As research and development continue, the potential of MAA in various fields will likely expand. Its versatility as a building block, combined with the demand for high-performance materials, suggests a bright future for methacrylic acid and its derived products. From improving the durability of our everyday objects to contributing to advancements in medicine and sustainable technologies, methacrylic acid remains a crucial ingredient in shaping a better future.

In conclusion, while often unseen, methacrylic acid plays a pivotal role in a multitude of industries. Its ability to form versatile polymers makes it a critical component in countless products, and ongoing research promises even more innovative applications for this important chemical compound.

Reviews

There are no reviews yet.