Description

Linear Low-Density Polyethylene (LLDPE): The Flexible Workhorse of Modern Plastics

Linear Low-Density Polyethylene (LLDPE) might not be a household name, but it’s a ubiquitous material silently shaping our everyday lives. From grocery bags to agricultural films, this flexible and durable plastic plays a critical role in various industries. While often confused with its close cousin, Low-Density Polyethylene (LDPE), LLDPE boasts unique properties that make it the preferred choice for many applications.

What is LLDPE and How is it Made?

LLDPE is a copolymer of ethylene and a higher alpha-olefin, such as butene, hexene, or octene. This means it’s created by joining long chains of ethylene molecules (like LDPE) but with the added presence of a small amount of another larger molecule. This seemingly small difference has a significant impact on the final polymer’s properties.

The “linear” in LLDPE refers to the polymer chain’s structure. Unlike LDPE, which has extensive branching, LLDPE exhibits a more linear backbone with short branches. This linear structure allows for tighter packing of molecules, resulting in higher tensile strength, puncture resistance, and tear propagation resistance compared to LDPE.

LLDPE is typically produced using gas-phase or solution-phase polymerization processes, utilizing Ziegler-Natta or metallocene catalysts. These modern processes allow for precise control over the polymer’s properties, such as density, molecular weight, and comonomer content, enabling manufacturers to tailor LLDPE for specific application requirements.

Key Properties and Advantages:

LLDPE offers a compelling combination of properties that make it a versatile and valuable material:

- High Tensile Strength: LLDPE boasts superior tensile strength compared to LDPE, allowing it to withstand greater pulling forces without breaking.

- Enhanced Puncture and Tear Resistance: Its linear structure and short branches contribute to excellent puncture and tear resistance, making it ideal for demanding applications like packaging and agricultural films.

- Improved Flexibility and Elongation: While stronger than LDPE, LLDPE still retains excellent flexibility and elongation, allowing it to be stretched and molded into various shapes.

- Good Chemical Resistance: LLDPE exhibits good resistance to a wide range of chemicals, including acids, bases, and solvents.

- Lower Production Cost: LLDPE production generally requires less energy compared to LDPE, resulting in lower manufacturing costs.

- Recyclability: LLDPE is recyclable, contributing to sustainable waste management efforts.

Applications Across Industries:

The versatile properties of LLDPE make it a staple across numerous industries:

- Packaging: LLDPE is widely used in the packaging industry for films, bags, pouches, and wraps for food, consumer goods, and industrial products. Its puncture resistance and tear strength make it ideal for protecting goods during transport and storage.

- Agricultural Films: In agriculture, LLDPE is used for mulch films, greenhouse covers, and silage films. These films help to control weeds, regulate soil temperature, and preserve crops.

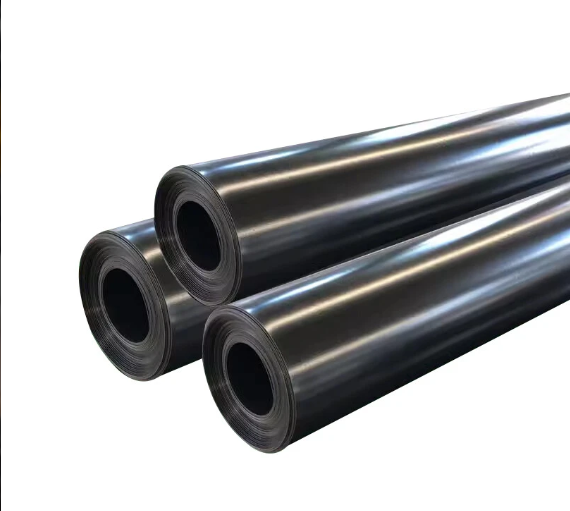

- Liners: LLDPE is used as a liner in various applications, including landfills, ponds, and canals, due to its excellent chemical resistance and low permeability.

- Cable Jacketing: LLDPE’s electrical insulation properties and flexibility make it suitable for cable jacketing applications.

- Toys and Housewares: LLDPE’s safety and durability make it a suitable material for the production of toys and housewares.

The Future of LLDPE:

The future of LLDPE looks bright. Ongoing research and development efforts are focused on improving its properties further and developing new applications. This includes:

- Enhanced Bio-Based LLDPE: Significant efforts are underway to develop LLDPE from renewable sources, such as sugarcane and corn, to reduce its reliance on fossil fuels and promote a more sustainable future.

- Metallocene-Catalyzed LLDPE: Advanced metallocene catalysts allow for even greater control over polymer properties, leading to LLDPE resins with tailored performance characteristics for specific applications.

- Improved Recyclability and Circularity: Continued advancements in recycling technologies aim to improve the recyclability of LLDPE and promote a circular economy where waste is minimized and resources are reused.

Conclusion:

Linear Low-Density Polyethylene (LLDPE) is a vital and versatile plastic material that plays a crucial role in numerous industries. Its unique blend of strength, flexibility, and cost-effectiveness makes it the preferred choice for a wide range of applications. As research continues to advance the properties and sustainability of LLDPE, its importance in our modern world is only set to grow. From packaging our food to protecting our crops, this flexible workhorse will continue to silently shape the world around us.

Reviews

There are no reviews yet.