Description

Indium Tin Oxide (ITO): The Unsung Hero of Modern Displays and Beyond

Indium Tin Oxide (ITO) might not be a household name, but it’s a crucial component in the technology we use every day. From the screens we stare at to the solar panels powering our homes, ITO plays a vital role. This seemingly humble material has revolutionized the world of electronics and continues to drive innovation in various fields.

So, what exactly is ITO? It’s a solid solution of indium(III) oxide (In₂O₃) and stannic oxide (SnO₂), typically containing around 90% In₂O₃ and 10% SnO₂ by weight. This specific mixture boasts a unique combination of properties that makes it indispensable for a wide range of applications.

Why is ITO so special? Its key characteristics include:

- Optical Transparency: ITO is highly transparent in the visible spectrum, allowing light to pass through with minimal distortion. This is critical for display technologies where clear visibility is paramount.

- Electrical Conductivity: Despite being transparent, ITO is a relatively good conductor of electricity. This allows it to function as an electrode without obscuring the image on the screen.

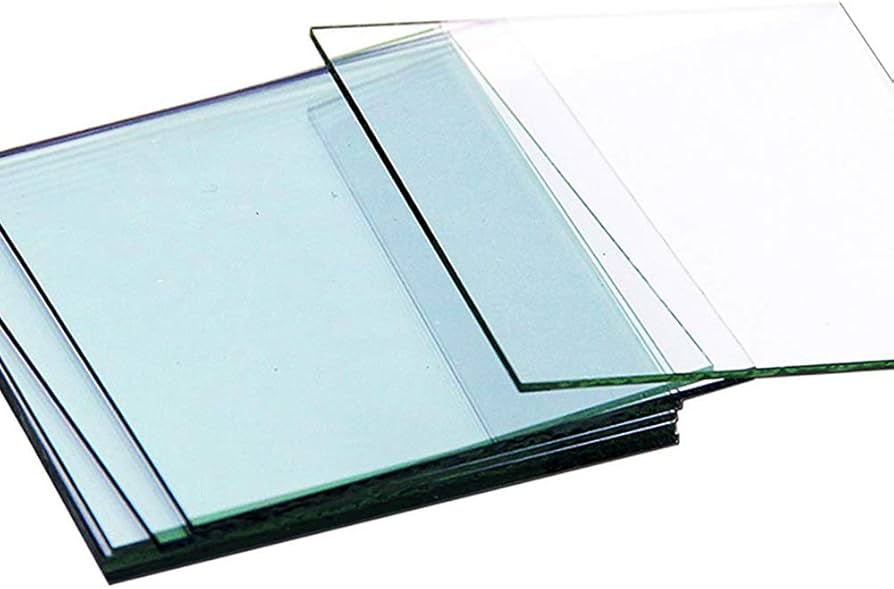

- Easy Deposition: ITO can be easily deposited as a thin film onto various substrates using techniques like sputtering, evaporation, and chemical vapor deposition. This versatility makes it compatible with diverse manufacturing processes.

- Chemical Stability: ITO exhibits good chemical stability, resisting degradation and oxidation under normal operating conditions. This ensures long-term performance and reliability.

Applications of ITO: A World of Possibilities

The unique combination of transparency and conductivity has made ITO a cornerstone of modern technology. Here’s a look at some of its key applications:

- Display Technologies: This is arguably the most well-known application of ITO. It’s used as a transparent electrode in LCDs (Liquid Crystal Displays), OLEDs (Organic Light Emitting Diodes), and touch screens. In these devices, ITO layers control the flow of electricity, allowing pixels to light up and enabling touch functionality.

- Solar Cells: ITO is used as a front electrode in thin-film solar cells, allowing sunlight to reach the active material while simultaneously collecting the generated electricity. Its high transparency maximizes light harvesting efficiency.

- Electromagnetic Interference (EMI) Shielding: Thin films of ITO can be applied to surfaces to provide EMI shielding, preventing electromagnetic radiation from interfering with sensitive electronic devices.

- Anti-Static Coatings: ITO coatings can dissipate static electricity, protecting sensitive electronic components from damage.

- Smart Windows: In smart windows, ITO layers can be used to control the amount of light and heat entering a building, helping to reduce energy consumption.

- Sensors: ITO can be used in various types of sensors, including gas sensors, pressure sensors, and biosensors, due to its sensitivity to changes in its electrical properties.

Challenges and the Search for Alternatives:

Despite its widespread use, ITO faces several challenges:

- Indium Scarcity: Indium is a relatively rare element, and concerns about its long-term availability and increasing cost have prompted research into alternative materials.

- Brittleness: ITO films can be brittle, making them susceptible to cracking and failure under stress.

- High Manufacturing Costs: The deposition techniques used to create high-quality ITO films can be expensive.

These challenges have spurred research into alternative transparent conductive oxides (TCOs), such as zinc oxide (ZnO), aluminum-doped zinc oxide (AZO), and graphene. While these alternatives show promise, they often fall short of ITO’s performance in terms of conductivity and transparency, particularly at lower wavelengths.

The Future of ITO and Transparent Conductive Materials:

While alternatives are being explored, ITO remains the dominant TCO in many applications. Ongoing research is focused on improving ITO’s properties, such as increasing its flexibility and reducing its indium content. Furthermore, researchers are exploring new deposition techniques to lower manufacturing costs and improve the scalability of ITO production.

The demand for transparent conductive materials is expected to continue to grow as display technologies evolve and new applications emerge in areas like flexible electronics, wearable devices, and advanced sensors. Whether ITO continues to reign supreme or is eventually replaced by a new generation of TCOs, the future of transparent conductivity is bright, promising to drive further innovation in the world of electronics and beyond.

In conclusion, Indium Tin Oxide is a vital material that has silently shaped the technology we rely on. While challenges remain, its unique combination of properties makes it a cornerstone of modern electronics and a driving force behind future innovation. As research continues to push the boundaries of material science, the world can expect even more groundbreaking applications of ITO and its next-generation counterparts.

Reviews

There are no reviews yet.