Description

Butyl Rubber (IIR): The Gas-Tight Champion of Synthetic Elastomers

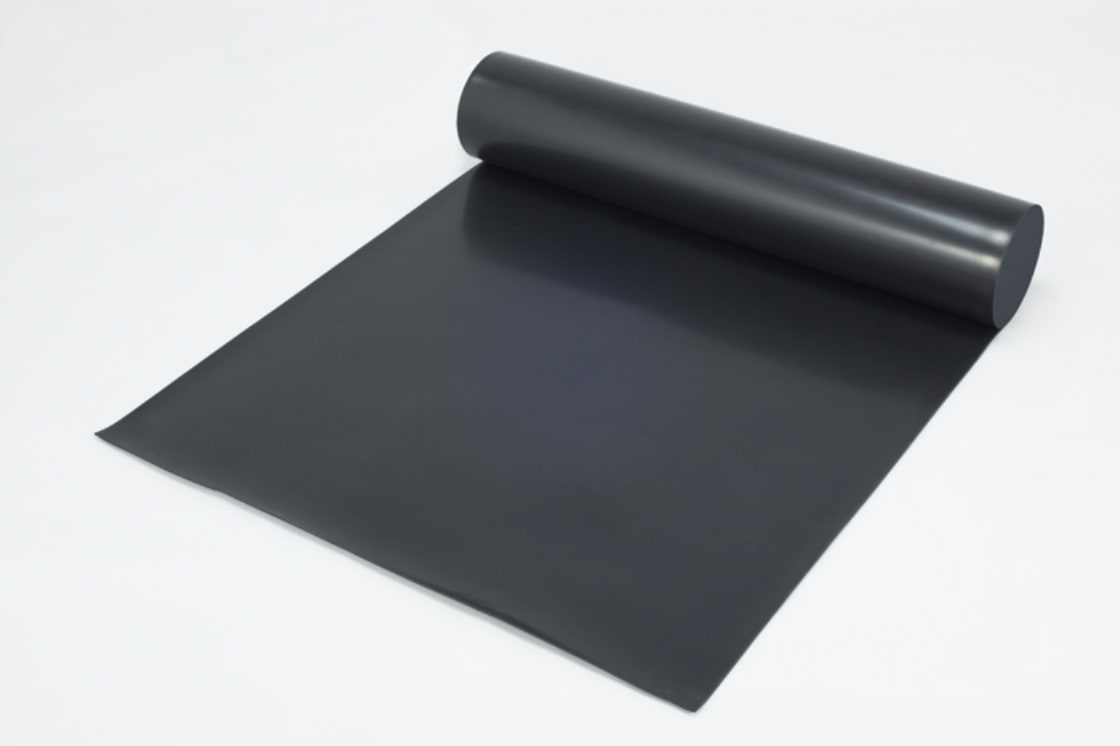

Butyl rubber, also known as isobutylene isoprene rubber (IIR), is a standout synthetic elastomer lauded for its exceptional gas impermeability, chemical resistance, and vibration damping properties. Discovered in the 1930s and commercially produced shortly after, butyl rubber has become a crucial component in a wide range of applications, from tires to pharmaceuticals. Its unique molecular structure gives it characteristics that make it indispensable in industries where maintaining a tight seal and withstanding harsh conditions are paramount.

The Secret’s in the Structure:

Butyl rubber is a copolymer composed primarily of isobutylene (typically 97-99%) with a small amount of isoprene (1-3%). This specific combination is key to its exceptional properties. The isobutylene component contributes to the polymer’s inherent flexibility and low permeability to gases. The addition of isoprene introduces unsaturation (double bonds) along the polymer chain, allowing for vulcanization. Vulcanization, or curing, involves crosslinking the polymer chains, strengthening the material and improving its elasticity and durability.

Key Properties that Set Butyl Rubber Apart:

- Exceptional Gas Impermeability: This is arguably butyl rubber’s most defining feature. Its tight molecular structure significantly restricts the passage of gases, making it ideal for applications requiring airtight or watertight seals.

- Excellent Chemical Resistance: Butyl rubber exhibits good resistance to a wide range of chemicals, including acids, alkalis, and polar solvents. This resistance makes it suitable for use in environments where exposure to corrosive substances is likely.

- Good Heat Resistance: Butyl rubber can withstand moderate temperatures without significant degradation, broadening its applicability.

- Vibration Damping: The material’s ability to absorb and dissipate vibration energy makes it an excellent choice for applications requiring noise and vibration reduction.

- Good Electrical Insulation: Butyl rubber is a non-conductive material, making it suitable for electrical insulation applications.

- Good Weathering Resistance: While not as outstanding as some other elastomers, butyl rubber offers reasonable resistance to ozone, sunlight, and aging.

A Versatile Material with a Broad Range of Applications:

The unique properties of butyl rubber make it a staple in numerous industries:

- Tire Industry: Butyl rubber is primarily used in the inner liners of tubeless tires due to its exceptional air retention capabilities. This maintains tire pressure and contributes to fuel efficiency.

- Pharmaceutical Industry: Due to its chemical inertness and low permeability, butyl rubber is widely used as stoppers for vials and bottles containing injectable medications. It ensures the sterility and integrity of the drugs.

- Adhesives and Sealants: Butyl rubber-based adhesives and sealants are used in construction, automotive, and industrial applications for providing airtight and watertight seals.

- Hoses and Belts: Butyl rubber’s chemical resistance and flexibility make it suitable for manufacturing hoses and belts used in various industrial applications.

- Consumer Goods: It can be found in products like chewing gum (as a base) and protective coatings.

- Bladders and Inflatable Equipment: Its air retention properties make it ideal for manufacturing bladders for sports equipment like basketballs and footballs, as well as inflatable boats and rafts.

Modified Butyl Rubbers: Expanding the Horizon:

Researchers have developed modified versions of butyl rubber to enhance specific properties and cater to specialized applications. Halogenated butyl rubber (chlorobutyl and bromobutyl rubber) offers improved adhesion to other elastomers and metals, making it particularly valuable in tire manufacturing.

The Future of Butyl Rubber:

While advancements in other elastomers are continuously being made, butyl rubber’s unparalleled gas impermeability and chemical resistance continue to solidify its position as a critical material in numerous industries. Ongoing research focuses on improving its overall performance, sustainability, and exploring novel applications. As technology evolves, butyl rubber is likely to remain a versatile and essential component in a wide range of products, ensuring airtight seals and reliable performance in demanding environments. Its unique blend of properties continues to make it a valuable asset in a world increasingly reliant on high-performance materials.

Reviews

There are no reviews yet.