Description

Automation Grade Wire Mesh: The Unsung Hero of Modern Manufacturing

In today’s competitive manufacturing landscape, efficiency and precision are paramount. While robots and automated systems often steal the spotlight, a crucial, yet often overlooked, component plays a vital role in ensuring smooth and reliable operation: automation grade wire mesh.

More than just a simple screen, automation grade wire mesh is engineered and manufactured to meet the demanding requirements of automated machinery and processes. It’s the unsung hero that facilitates filtration, separation, screening, and even conveying materials in a wide range of industries. From food processing and pharmaceuticals to automotive and aerospace, this specialized mesh contributes to enhanced productivity, improved product quality, and reduced downtime.

What Sets Automation Grade Wire Mesh Apart?

Unlike standard wire mesh, automation grade varieties are crafted with exacting standards, focusing on several key characteristics:

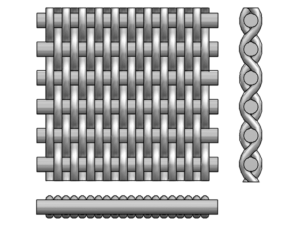

Precise Weave and Aperture: Consistency in the weave pattern and aperture size is critical for predictable performance. Automated machinery relies on uniform filtration or separation, and any deviation can lead to inconsistent results or machine malfunctions.

High Tensile Strength: Automation grade mesh often undergoes specific treatments to increase its tensile strength and resistance to wear and tear. This ensures durability and minimizes the risk of tearing or deformation under constant use.

Cleanliness and Surface Finish: Contamination can wreak havoc on sensitive manufacturing processes. Automation grade mesh is often meticulously cleaned and polished to eliminate any residue or burrs that could interfere with product quality or machine operation.

Material Selection: The choice of material, typically stainless steel, but also including materials like nickel alloys or specialized polymers, depends on the application. Factors like corrosion resistance, temperature tolerance, and contact with specific chemicals or materials are carefully considered.

Dimensional Accuracy: Precisely cut and formed to specific dimensions, automation grade wire mesh ensures a perfect fit within machinery and minimizes the need for on-site adjustments.

The Benefits of Using Automation Grade Wire Mesh:

The investment in automation grade wire mesh translates into significant advantages for manufacturers:

Increased Efficiency: Consistent performance and reliability minimize downtime caused by screen failures or inconsistencies, leading to greater operational efficiency.

Improved Product Quality: Precise filtration and separation capabilities ensure a higher quality end product, meeting stringent regulatory requirements and exceeding customer expectations.

Reduced Maintenance Costs: Durable materials and robust construction minimize the need for frequent repairs and replacements, reducing overall maintenance costs.

Enhanced Safety: High-quality mesh contributes to a safer working environment by preventing debris from entering machinery or contaminating work areas.

Optimized Automation: Automation grade mesh complements automated systems by ensuring consistent and predictable performance, allowing them to operate at their full potential.

Applications Across Diverse Industries:

The versatility of automation grade wire mesh makes it suitable for a wide array of applications:

Food Processing: Filtering liquids, separating solids, sifting powders, and conveying ingredients on automated conveyor belts.

Pharmaceuticals: Filtering sterile solutions, screening powders, and sieving granules to ensure product purity and consistency.

Automotive: Filtering paints, coating materials, and cooling fluids in automated painting and assembly lines.

Aerospace: Filtering hydraulic fluids, separating metal powders in additive manufacturing, and contributing to the precision manufacturing of aircraft components.

Plastics Manufacturing: Filtering molten plastics, screening recycled materials, and contributing to efficient injection molding processes.

Conclusion:

Automation grade wire mesh is an essential component of modern manufacturing, contributing significantly to efficiency, quality, and safety. While it may not be the most glamorous aspect of automation, its reliable performance is crucial for keeping the wheels of industry turning smoothly. By choosing high-quality automation grade wire mesh, manufacturers can unlock the full potential of their automated systems and achieve optimal results in today’s demanding marketplace. As automation continues to evolve, so too will the technology and applications of this vital material, solidifying its position as the unsung hero of modern manufacturing.

Reviews

There are no reviews yet.