Description

Activated Carbon Fiber: A Powerful Adsorbent Revolutionizing Industries

In the realm of advanced materials, activated carbon fiber (ACF) stands out as a potent and versatile adsorbent, quietly revolutionizing industries from environmental remediation to energy storage. Unlike its more common granular activated carbon (GAC) cousin, ACF boasts unique properties that make it a superior choice for specific applications where speed, efficiency, and surface area are paramount.

What is Activated Carbon Fiber?

Activated carbon fiber is essentially carbon fiber that has undergone a process to increase its surface area dramatically. This “activation” process, which can involve chemical or physical methods, creates a vast network of pores on the fiber’s surface. These pores, ranging in size from micropores to macropores, are the key to ACF’s exceptional adsorptive capabilities.

The starting material for ACF can vary, but common sources include rayon, polyacrylonitrile (PAN), and pitch. These materials are first converted into carbon fibers through a process called carbonization. Then, activation techniques like steam activation, chemical activation with alkali hydroxides or phosphoric acid, or even microwave irradiation are employed to create the porous structure.

Advantages of ACF over Granular Activated Carbon (GAC):

While both ACF and GAC are effective adsorbents, ACF offers several distinct advantages:

- Faster Adsorption Kinetics: The fiber form of ACF provides a shorter diffusion path for molecules to reach the active adsorption sites within the pores. This translates to significantly faster adsorption rates compared to GAC, making ACF ideal for applications demanding rapid removal of contaminants.

- Higher Surface Area: ACF generally possesses a higher specific surface area than GAC, meaning more surface area per unit mass is available for adsorption. This leads to higher adsorption capacities and improved efficiency.

- Ease of Regeneration: ACF can be readily regenerated by various methods, including thermal swing adsorption (TSA), pressure swing adsorption (PSA), and chemical regeneration. Its fibrous structure allows for more efficient gas flow and heat transfer during regeneration, resulting in lower energy consumption.

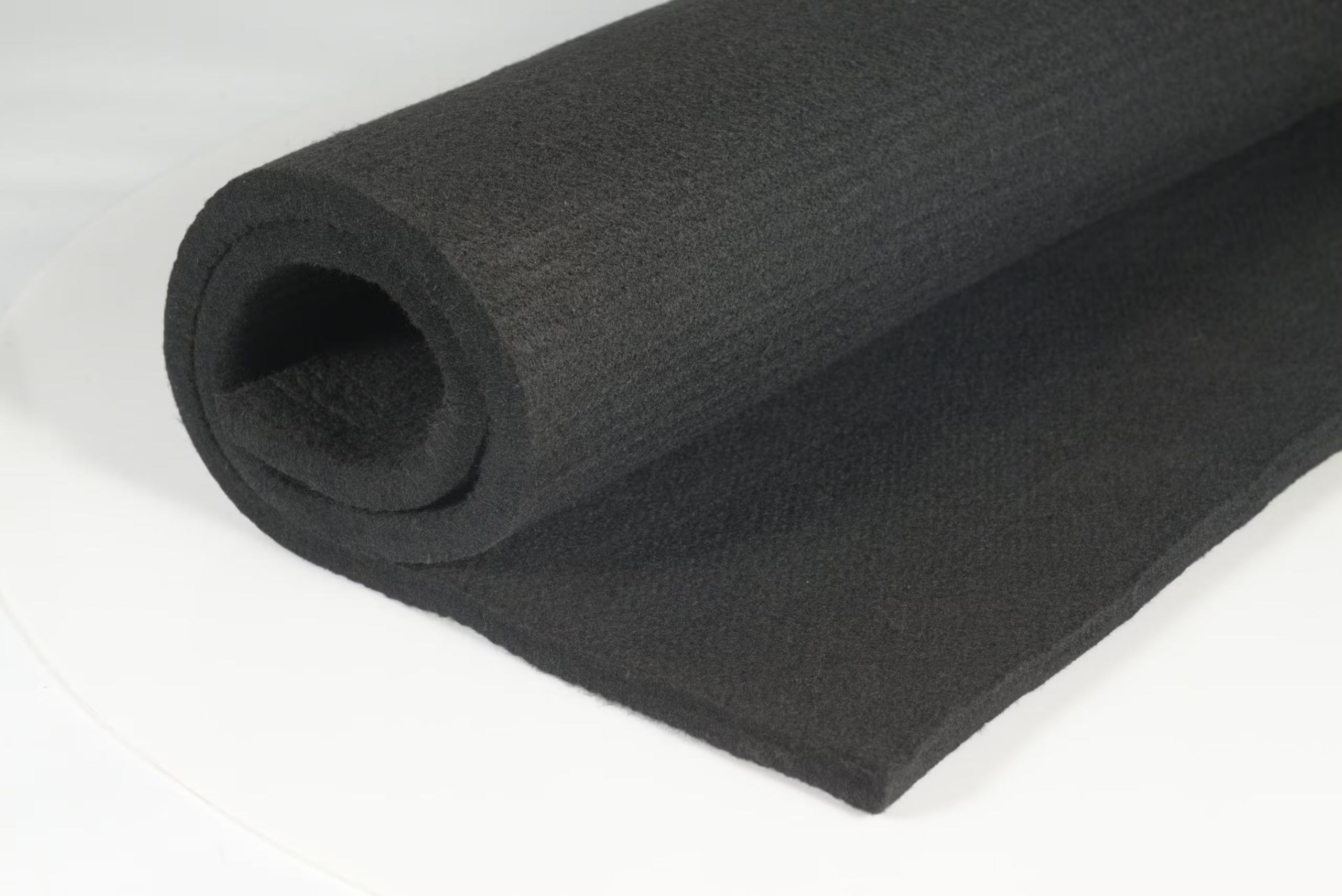

- Versatility in Form: ACF can be manufactured in various forms, including woven fabrics, felts, non-woven fabrics, and even incorporated into composite materials. This versatility allows for tailored solutions for a wide range of applications.

Key Applications of Activated Carbon Fiber:

The unique properties of ACF have led to its adoption in a diverse range of applications, including:

- Air Purification: ACF filters are widely used in air purifiers, HVAC systems, and respirators to remove volatile organic compounds (VOCs), odors, and other airborne pollutants. Its fast adsorption kinetics and high surface area make it highly effective in capturing even low concentrations of contaminants.

- Water Treatment: ACF can effectively remove pollutants from water, including organic compounds, heavy metals, and pharmaceuticals. Its ability to be formed into various shapes allows for easy integration into existing water treatment systems.

- Catalysis and Catalyst Support: Due to its high surface area and chemical inertness, ACF can serve as a support material for catalysts in various chemical reactions. Its unique pore structure can also influence the selectivity of the catalyst.

- Energy Storage: ACF is being explored as a promising material for electrodes in supercapacitors and batteries. Its high surface area and electrical conductivity make it ideal for storing electrical energy.

- Medical Applications: ACF-based materials are used in wound dressings for their ability to absorb exudate and control odor. They are also being investigated for drug delivery applications.

- Protective Clothing: ACF is incorporated into protective clothing to absorb chemical and biological warfare agents, providing a critical layer of defense for first responders and military personnel.

The Future of Activated Carbon Fiber:

The future of ACF looks bright, with ongoing research and development focused on:

- Improving Production Efficiency: Researchers are constantly working on optimizing the production process to reduce costs and improve the overall performance of ACF.

- Developing Novel Activation Methods: Exploration of new activation techniques aims to further enhance the surface area, pore size distribution, and other key properties of ACF.

- Exploring New Applications: Scientists and engineers are continually discovering new applications for ACF in emerging fields such as microelectronics, biomedical engineering, and advanced materials.

Conclusion:

Activated carbon fiber is a powerful and versatile material with a wide range of applications. Its superior adsorption properties, coupled with its versatility in form, make it a valuable asset in various industries. As research and development continue to advance, ACF is poised to play an increasingly important role in addressing global challenges related to environmental protection, energy storage, and human health. Its contribution to a cleaner, more sustainable future is undeniable.

Reviews

There are no reviews yet.