Description

MDI: The Ubiquitous Building Block of Modern Life

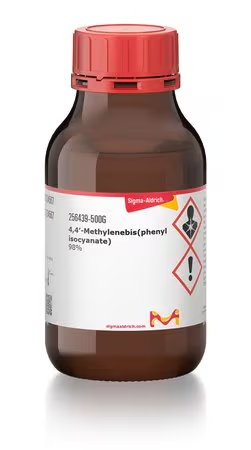

In the vast landscape of industrial chemistry, few compounds are as versatile and impactful as 4,4’-Methylenebis(phenyl isocyanate), more commonly known by its acronym, MDI. While its chemical name might sound complex, MDI is an essential foundational component that underpins a remarkable array of products and innovations, significantly shaping our daily lives, from the insulation in our homes to the comfort of our car seats.

What is MDI?

MDI is an organic compound belonging to the diisocyanate family. In its purest form, 4,4′-MDI is a white to pale yellow solid. However, in commercial applications, MDI often refers to a mixture of isomers, including 2,4′-MDI and 2,2′-MDI, and more importantly, its polymeric form known as polymeric MDI (pMDI). This pMDI is a dark brown liquid and is the most widely used variant in industry, containing a distribution of the pure MDI monomer and a series of higher molecular weight oligomers.

The key to MDI’s utility lies in its highly reactive isocyanate (-NCO) functional groups. These groups readily react with compounds containing hydroxyl (-OH) groups, such as polyols, to form urethane linkages. This reaction is the cornerstone of polyurethane chemistry.

Production of MDI

MDI is primarily produced through the phosgenation of diaminodiphenylmethane (MDA). This multi-step process involves the reaction of aniline and formaldehyde to form MDA, which is then reacted with phosgene to yield MDI. The specific conditions of the phosgenation process allow for the control of the monomeric and polymeric MDI ratios, tailoring the product for various applications.

The Versatility of Applications

The ability of MDI to form strong, durable, and highly customizable polyurethane materials makes it indispensable across numerous industries:

- Rigid Foams (Insulation): This is by far the largest application for MDI. Polyurethane rigid foams, predominantly made with pMDI, boast exceptional thermal insulation properties. They are crucial for:

- Construction: Wall, roof, and floor insulation in residential and commercial buildings, contributing significantly to energy efficiency.

- Appliances: Refrigerators, freezers, and water heaters rely on polyurethane foam for their excellent insulating capabilities.

- Piping and Tanks: Insulating industrial pipelines and storage tanks.

- Flexible Foams: While toluene diisocyanate (TDI) is more common for very soft foams (like furniture cushions), MDI can be used to produce specific types of flexible foams, particularly those requiring higher load-bearing capabilities or specific processing characteristics.

- Adhesives, Sealants, and Binders: MDI-based polyurethanes offer superior bonding strength and flexibility, making them ideal for:

- Construction: Adhesives for panel bonding, subflooring, and sealing gaps.

- Wood Products: Binders for engineered wood products like Oriented Strand Board (OSB) and Medium Density Fiberboard (MDF).

- Automotive: Bonding various components in vehicle assembly.

- Footwear: Adhesives for shoe soles.

- Coatings, Elastomers, and Binders (CASE):

- Coatings: MDI-based polyurethanes provide durable, abrasion-resistant, and chemically resistant coatings for floors, automotive parts, and various industrial equipment.

- Elastomers: Used in the production of high-performance elastomers for applications requiring durability, flexibility, and resistance to abrasion, such as wheels, rollers, and even some types of synthetic fibers.

- Binders: Used in foundry resins, rubber bonding applications, and as binders for recycled materials like crumb rubber.

- Automotive Industry: MDI contributes to a wide range of automotive components, including seating foams, interior trim, steering wheels, dashboards, and sound insulation materials, enhancing comfort, safety, and fuel efficiency.

Safety, Health, and Environment

MDI, like many industrial chemicals, requires careful handling. It is classified as an irritant and a respiratory sensitizer. Inhalation of MDI vapors or aerosols, especially in high concentrations, can cause respiratory irritation, asthma-like symptoms, and in sensitized individuals, severe allergic reactions. Skin and eye contact can also cause irritation.

However, it is crucial to distinguish between the raw chemical and the final products. Once MDI has reacted with a polyol and fully cured into a polyurethane material, the highly reactive isocyanate groups are consumed, and the finished product is generally considered inert and safe for its intended use. Safety precautions during manufacturing, transportation, and application of MDI include rigorous ventilation, personal protective equipment (PPE), and adherence to strict industrial hygiene practices.

From an environmental perspective, MDI itself has low biodegradability. However, the industry is continuously working towards more sustainable practices, including recycling polyurethane waste and developing bio-based polyols to reduce reliance on petrochemicals.

The Future of MDI

As global demand for energy efficiency, lightweight materials, and durable goods continues to grow, the importance of MDI is set to expand. Innovations in polyurethane chemistry, driven by MDI, are leading to advanced materials with enhanced properties, specialized functionalities, and improved sustainability profiles. From next-generation insulation to high-performance composite materials, MDI remains a cornerstone of material science, silently contributing to the comfort, safety, and efficiency of our modern world.

Reviews

There are no reviews yet.