Description

Polymeric Flocculants: Clearing the Waters with Long Chains

In a variety of industries, from wastewater treatment to mining, the efficient separation of solids from liquids is crucial. While gravity alone can sometimes do the trick, often the suspended particles are too small and stable to settle on their own. This is where polymeric flocculants come into play, offering a powerful and versatile solution to clarify even the cloudiest suspensions.

What are Polymeric Flocculants?

Polymeric flocculants are large, chain-like molecules (polymers) designed to promote the aggregation of small, dispersed particles into larger, more easily settleable flocs. These polymers are typically synthetic, although naturally derived options are gaining traction due to environmental concerns. Their effectiveness stems from their unique ability to bridge and bind particles together, overcoming the forces that keep them suspended.

How They Work: A Molecular Glue

The mechanism of polymeric flocculation revolves around several key principles:

- Charge Neutralization: Many suspended particles carry surface charges that repel each other, preventing aggregation. Polymeric flocculants can carry opposite charges, neutralizing these repulsive forces and allowing particles to come closer together. These charge neutralization interactions are particularly important for cationic polymers.

- Bridging: The long chain structure of the polymer is crucial. These chains can adsorb onto the surface of multiple particles simultaneously, creating a “bridge” between them. By linking particles together, the flocculant effectively creates larger, heavier aggregates that settle more readily.

- Enmeshment: In some cases, particularly with high-molecular-weight polymers, the long chains can physically entangle and trap particles within their network. This enmeshment contributes to the formation of robust and stable flocs.

Types of Polymeric Flocculants:

Polymeric flocculants are broadly classified based on their charge:

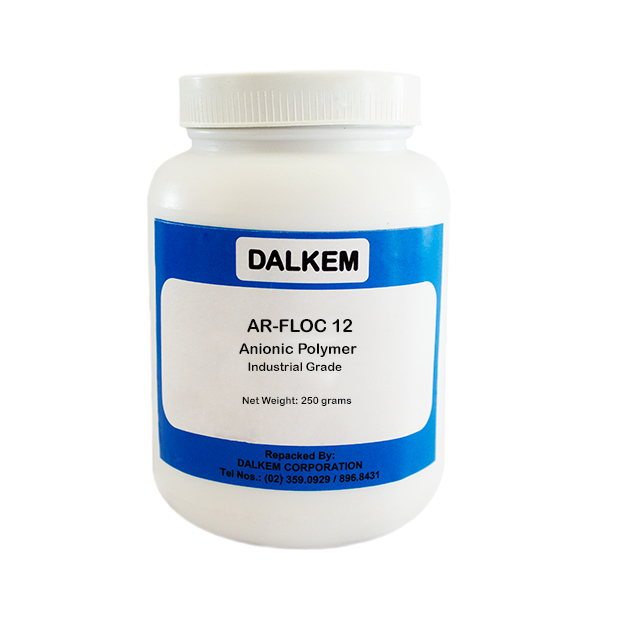

- Anionic Polymeric Flocculants: These polymers carry a negative charge and are highly effective in treating suspensions with positively charged particles. They are commonly used in wastewater treatment for clarifying sewage and industrial effluents.

- Cationic Polymeric Flocculants: Carrying a positive charge, these flocculants are used to treat suspensions with negatively charged particles, such as those found in mineral processing and paper manufacturing. They are also effective in sludge dewatering.

- Nonionic Polymeric Flocculants: These polymers have no net charge and rely primarily on bridging and enmeshment mechanisms for flocculation. They are often used in situations where charge neutralization is not a significant factor.

Applications Across Industries:

The versatility of polymeric flocculants makes them indispensable in a wide range of industries:

- Wastewater Treatment: Polymeric flocculants are vital for removing suspended solids from municipal and industrial wastewater, ensuring cleaner water discharge and protecting the environment.

- Mining: In mineral processing, they are used to separate valuable minerals from unwanted gangue material, improving extraction efficiency.

- Paper Manufacturing: Flocculants help retain fiber and fillers during papermaking, leading to improved paper quality and reduced waste.

- Oil and Gas: They are used in enhanced oil recovery and for treating produced water, separating oil and water phases.

- Food Processing: Polymeric flocculants are used in clarifying fruit juices, sugar refining, and other food processing applications.

Advantages and Considerations:

Polymeric flocculants offer several advantages over traditional flocculants:

- High Efficiency: They require relatively low dosages to achieve effective flocculation.

- Strong Flocs: The flocs formed are typically stronger and more resistant to breakage than those formed by inorganic coagulants.

- Versatility: A wide range of polymeric flocculants are available, allowing for tailored solutions to specific applications.

However, there are also considerations to keep in mind:

- Cost: Polymeric flocculants can be more expensive than inorganic coagulants.

- Dosage Optimization: Finding the optimal dosage is crucial for achieving maximum effectiveness and avoiding over-flocculation, which can hinder settling.

- Environmental Impact: While synthetic polymers are widely used, research is ongoing to develop more sustainable and biodegradable alternatives.

The Future of Flocculation:

The field of polymeric flocculants is constantly evolving. Research is focused on developing:

- Biodegradable and Bio-based Polymers: Minimizing the environmental impact of flocculation is a major driving force.

- Smart Polymers: Polymers that respond to specific conditions, such as pH or temperature, allowing for more precise and efficient flocculation.

- Tailored Polymers: Polymers designed for specific applications, optimizing performance for particular types of suspensions.

In conclusion, polymeric flocculants are essential tools for solid-liquid separation across numerous industries. Their ability to effectively aggregate small particles into easily separable flocs makes them indispensable for clarifying water, processing minerals, and improving various industrial processes. As research continues to advance, we can expect even more innovative and sustainable flocculation solutions in the future.

Reviews

There are no reviews yet.