Description

Nylon 66: The Workhorse Polyamide Shaping Our World

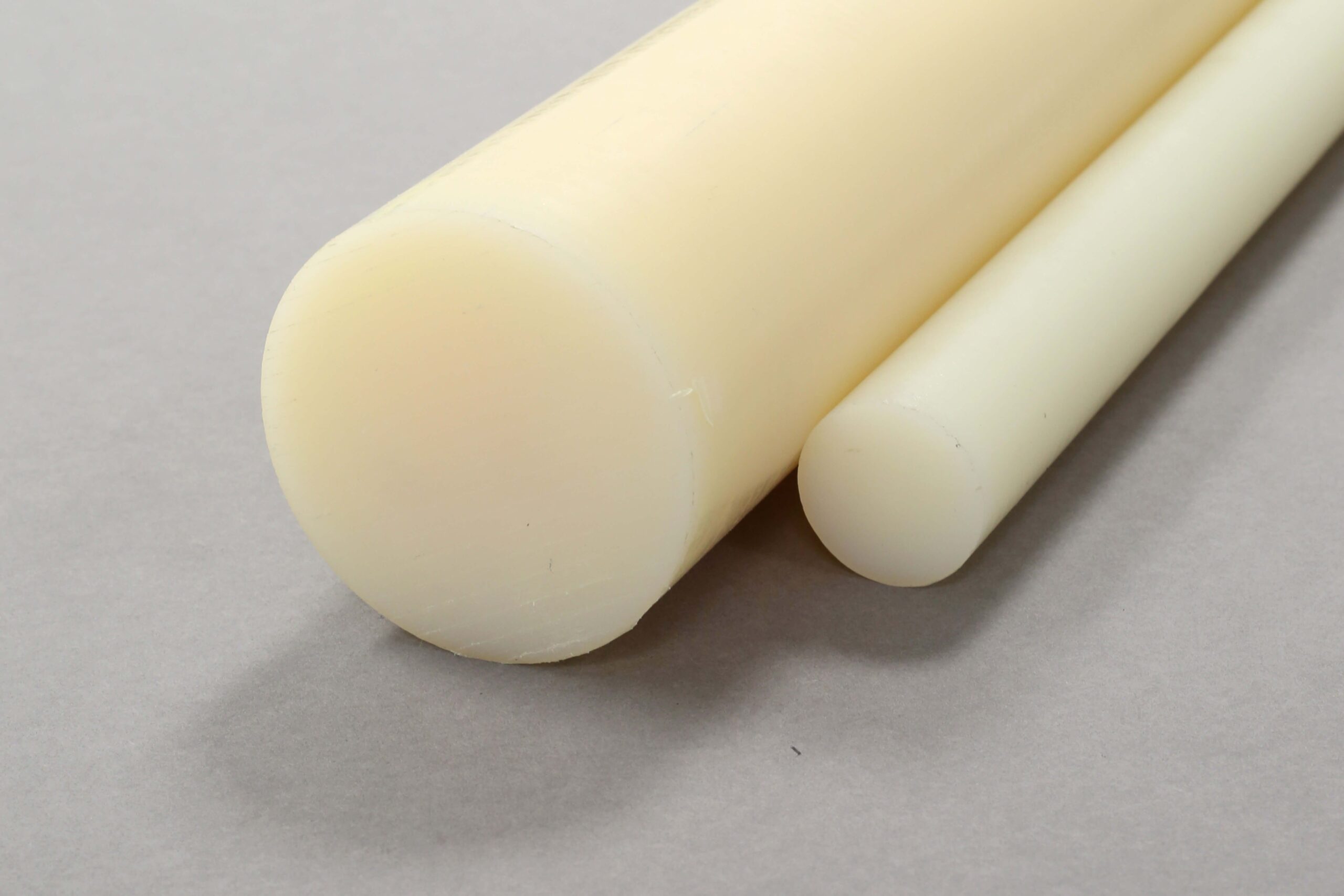

Nylon 66, also known as poly(hexamethylene adipamide), is a versatile and widely used synthetic polyamide that has become a cornerstone of modern industry. From rugged textiles and durable automotive parts to precision medical devices and everyday household items, its unique combination of strength, heat resistance, and chemical resilience makes it a material of choice across numerous applications.

A History of Innovation:

Nylon 66 was one of the first commercially successful synthetic polymers, developed by Wallace Carothers and his team at DuPont in the 1930s. Initially conceived as a strong and elastic fiber to replace silk, its introduction in 1938 revolutionized the textile industry, famously in the form of nylon stockings. This initial success paved the way for the exploration of its broader potential across diverse sectors.

The Science Behind the Strength:

Nylon 66 derives its desirable properties from its unique molecular structure. It’s formed by the condensation polymerization of two monomers: hexamethylenediamine and adipic acid. During this process, a molecule of water is released for each amide bond (the “Nylon” bond) that forms, linking the monomers into long chains.

The key factors contributing to its strength and resilience include:

- Strong Intermolecular Forces: The amide groups in the polymer chains are capable of forming strong hydrogen bonds with each other. These bonds create a network of interlocking forces that prevent the polymer chains from easily sliding past one another, leading to high tensile strength and toughness.

- Crystallinity: Nylon 66 exhibits a high degree of crystallinity, meaning its polymer chains are arranged in a highly ordered manner. Crystalline regions provide greater strength and stiffness compared to amorphous (disordered) regions.

- High Melting Point: Nylon 66 has a relatively high melting point (around 265°C or 509°F), allowing it to retain its properties at elevated temperatures, making it suitable for applications requiring thermal stability.

A World of Applications:

The unique characteristics of Nylon 66 have led to its widespread adoption in a plethora of applications:

- Textiles: From apparel like stockings, sportswear, and outerwear to carpets and upholstery, Nylon 66’s strength, elasticity, and resistance to abrasion make it a valuable fiber for diverse textile applications.

- Automotive Industry: Its heat resistance, chemical resilience, and high strength-to-weight ratio make Nylon 66 ideal for components such as radiator end tanks, engine covers, and connectors.

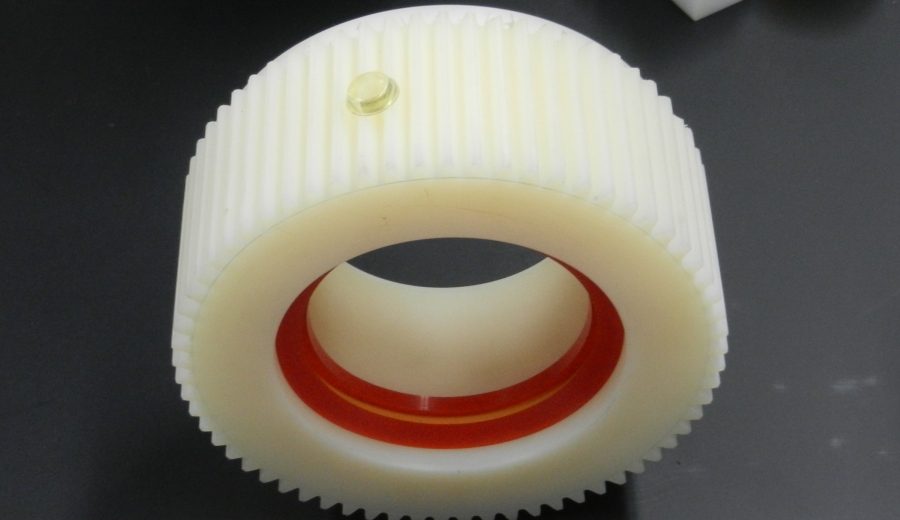

- Electrical and Electronics: Nylon 66 exhibits good electrical insulation properties and can withstand high temperatures, making it suitable for connectors, housings, and other electrical components.

- Industrial Applications: Gears, bearings, bushings, and other mechanical parts benefit from Nylon 66’s wear resistance and ability to operate under demanding conditions.

- Medical Devices: The biocompatibility of certain grades of Nylon 66 makes it suitable for medical implants, sutures, and other medical applications.

- Consumer Goods: From toothbrush bristles and fishing line to cable ties and zippers, Nylon 66 finds its way into countless everyday products.

Advantages and Considerations:

While Nylon 66 boasts numerous advantages, it’s important to acknowledge its limitations:

Advantages:

- High strength and toughness: Excellent resistance to impact and wear.

- Good heat resistance: Can withstand elevated temperatures without significant property degradation.

- Chemical resistance: Resistant to many solvents, oils, and fuels.

- Good processability: Can be easily molded, extruded, and spun into fibers.

- Cost-effective: Relatively inexpensive compared to some other high-performance polymers.

Considerations:

- Moisture absorption: Nylon 66 can absorb moisture from the environment, which can affect its mechanical properties and dimensional stability.

- Poor UV resistance: Prolonged exposure to ultraviolet (UV) radiation can cause degradation and discoloration.

- Flammability: Nylon 66 is flammable and requires flame retardants for some applications.

The Future of Nylon 66:

Despite its long history, Nylon 66 continues to evolve and adapt to meet the demands of a changing world. Ongoing research and development are focused on:

- Developing bio-based Nylon 66: Exploring sustainable alternatives to petroleum-based monomers to reduce its environmental footprint.

- Improving UV resistance and flame retardancy: Enhancing its performance in outdoor and safety-critical applications.

- Developing new grades with enhanced properties: Tailoring Nylon 66 to specific applications by incorporating additives and modifiers.

Conclusion:

Nylon 66 remains a powerhouse polymer with a remarkable track record of innovation and widespread adoption. Its exceptional blend of strength, heat resistance, and chemical resilience has cemented its position as a vital material in countless industries. As research continues to refine and enhance its properties, Nylon 66 is poised to play an even greater role in shaping the future of materials science.

Reviews

There are no reviews yet.