Description

Polyetherimide (PEI): A High-Performance Thermoplastic for Demanding Applications

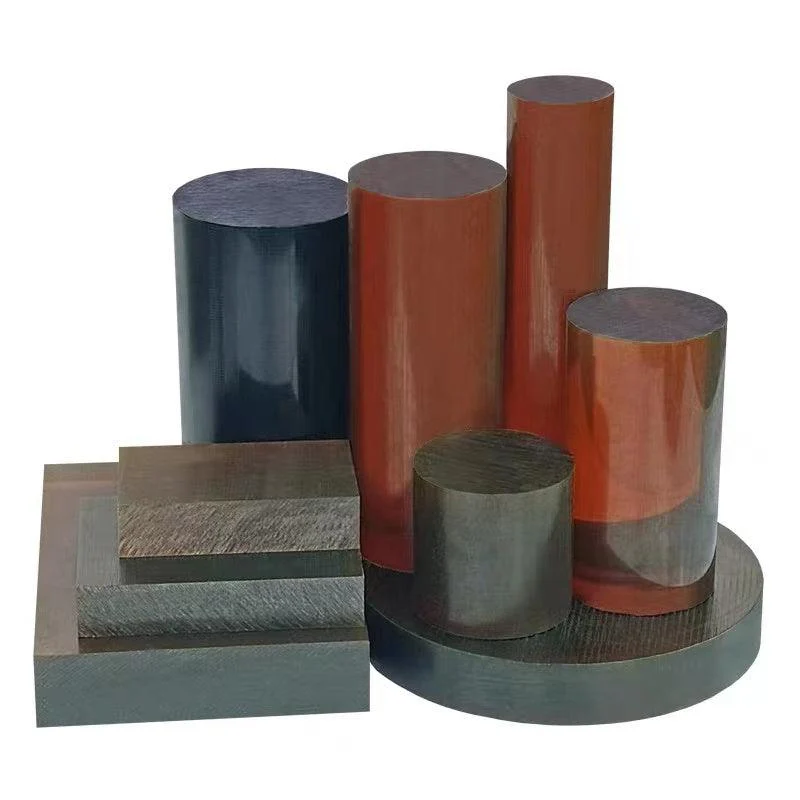

Polyetherimide (PEI), often recognized by its trademarked name Ultem™, is a high-performance, amorphous thermoplastic polymer renowned for its exceptional strength, heat resistance, and chemical stability. This unique combination of properties makes it a popular choice for a wide range of demanding applications across diverse industries.

What is Polyetherimide?

PEI belongs to the polyimide family, but unlike its thermoset counterparts, PEI is a thermoplastic. This means it can be repeatedly softened by heating and solidified by cooling, allowing for easier processing and recyclability. It’s produced through a polycondensation reaction involving a dianhydride and a diamine monomer, resulting in a polymer chain characterized by ether linkages (C-O-C) and imide groups (C(=O)-N-C(=O)). These structural features contribute to its impressive thermal and mechanical properties.

Key Properties and Benefits:

PEI boasts a compelling array of characteristics that make it a valuable material for engineers and designers:

- High Heat Resistance: PEI possesses a high glass transition temperature (Tg) typically around 217°C (423°F), allowing it to maintain its mechanical performance at elevated temperatures. This makes it ideal for applications requiring continuous use at high temperatures.

- Exceptional Strength and Stiffness: PEI exhibits excellent tensile strength, flexural modulus, and impact resistance, providing structural integrity even under stressful conditions.

- Chemical Resistance: PEI demonstrates resistance to a wide range of chemicals, including hydrocarbons, alcohols, acids, and bases. This broad compatibility makes it suitable for harsh environments where exposure to various substances is expected.

- Dimensional Stability: PEI exhibits low creep and a low coefficient of thermal expansion, ensuring dimensional stability over a wide temperature range. This is crucial for precision applications where dimensional accuracy is paramount.

- Flame Retardancy: PEI is inherently flame retardant without the need for added additives. It meets stringent flammability standards, making it suitable for applications requiring fire safety.

- Electrical Properties: PEI possesses good dielectric strength and insulation resistance, making it a viable material for electrical and electronic components.

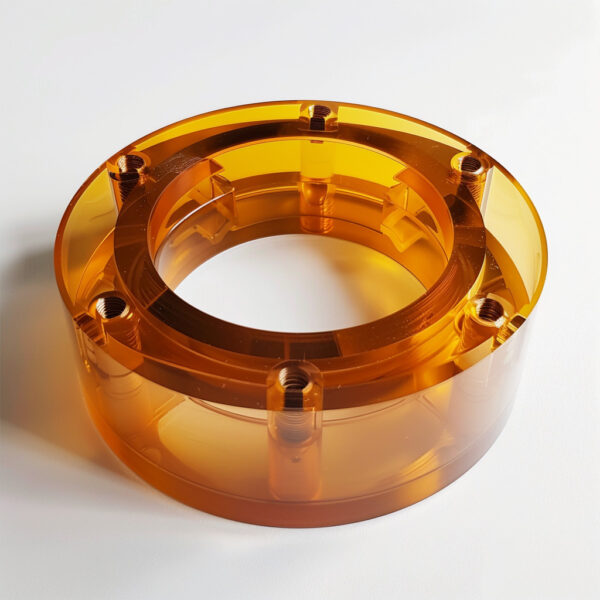

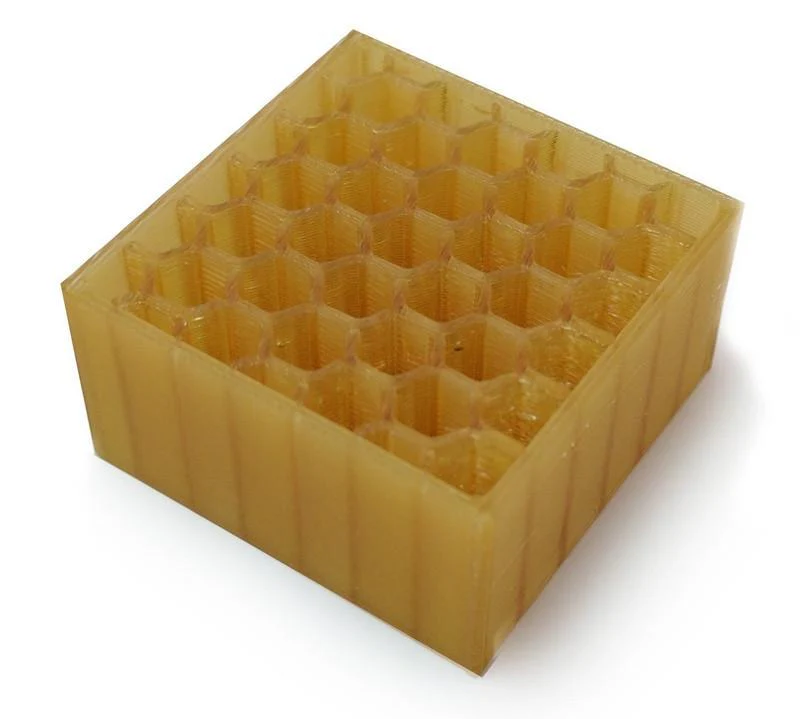

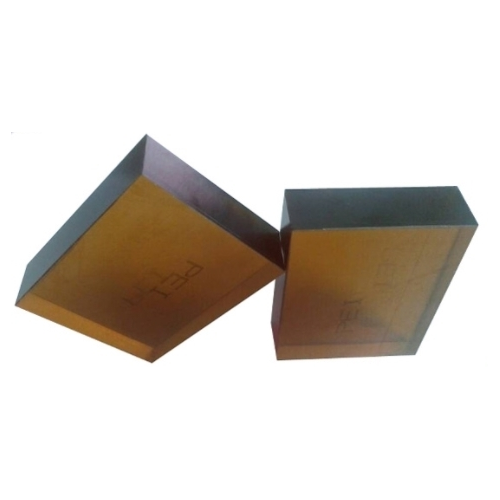

- Transparency: In its unfilled form, PEI is amber-colored and transparent, allowing for visual inspection and aesthetic applications.

Applications Across Industries:

The unique properties of PEI have led to its widespread adoption in numerous demanding applications:

- Aerospace: PEI is a crucial material in aircraft interiors, structural components, and engine parts due to its lightweight, high strength, and flame retardancy.

- Automotive: Under-the-hood components, connectors, sensors, and fuel handling systems benefit from PEI’s heat resistance, chemical resistance, and durability.

- Electronics: PEI is used extensively in circuit boards, connectors, insulators, and housings due to its electrical properties, dimensional stability, and high-temperature performance.

- Medical: PEI is biocompatible and sterilizable, making it suitable for medical devices, surgical instruments, and dental applications.

- Industrial: PEI finds use in pump impellers, valve bodies, manifolds, and other industrial components requiring high strength, chemical resistance, and heat resistance.

- Food Processing: PEI’s chemical resistance and ability to withstand repeated cleaning cycles make it suitable for food processing equipment.

Processing Methods:

PEI can be processed using various methods, including:

- Injection Molding: The most common processing method for PEI, allowing for the production of complex shapes with high precision.

- Extrusion: Used to produce PEI sheets, films, rods, and tubes.

- Thermoforming: Used to shape PEI sheets into desired forms.

- Machining: PEI can be easily machined to tight tolerances.

- 3D Printing: PEI filaments are available for fused deposition modeling (FDM) 3D printing, enabling the creation of complex geometries and prototypes.

Challenges and Considerations:

Despite its many advantages, PEI also presents some challenges:

- Cost: PEI is generally more expensive than commodity thermoplastics due to its specialized production process.

- Moisture Absorption: PEI can absorb moisture, which can affect its properties and processability. Proper drying is often required before processing.

- Limited Color Options: While transparent in its natural state, PEI is often limited to darker colors when pigments are added.

The Future of PEI:

Ongoing research and development continue to expand the applications of PEI. Efforts are focused on:

- Developing new PEI blends and composites: Blending PEI with other polymers or reinforcing it with fibers can enhance its properties and reduce costs.

- Improving processing techniques: Optimizing processing methods can lead to more efficient and cost-effective manufacturing.

- Expanding applications in emerging technologies: PEI is being explored for use in advanced battery technologies, fuel cells, and other cutting-edge applications.

Conclusion:

Polyetherimide (PEI) remains a critical high-performance thermoplastic, offering a unique combination of properties that make it indispensable for demanding applications across numerous industries. Its exceptional heat resistance, strength, chemical stability, and flame retardancy continue to drive its adoption in a wide range of challenging environments, solidifying its position as a key material for innovation and technological advancement. As research and development continue, PEI is poised to play an even greater role in shaping the future of various industries.

Reviews

There are no reviews yet.