Description

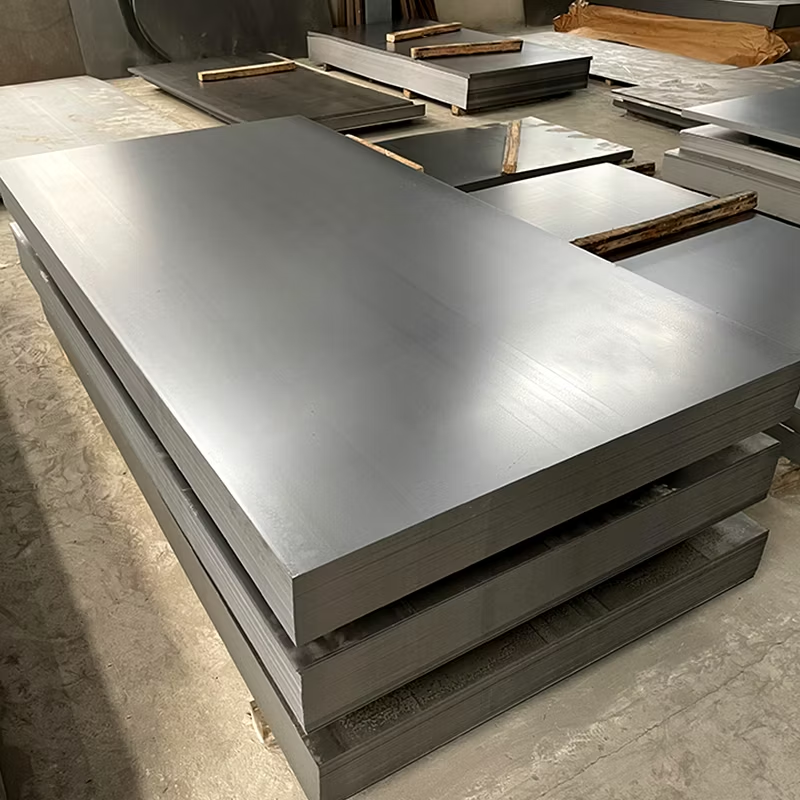

Cold Rolled Sheets: Precision and Versatility in Metal Manufacturing

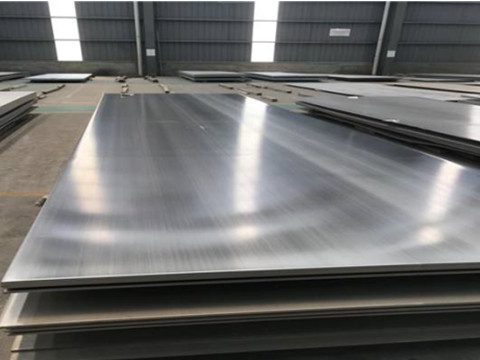

Cold rolled sheets are a staple in the metalworking industry, prized for their superior surface finish, tight tolerances, and enhanced strength. Unlike hot rolled sheets, which are processed at high temperatures, cold rolling takes place near room temperature. This key difference gives cold rolled sheets a distinct set of characteristics that make them ideal for a wide range of applications.

What is Cold Rolling?

Cold rolling is a metal forming process where hot rolled steel is further processed at room temperature. The process involves passing the hot rolled steel through a series of rollers to gradually reduce its thickness. This cold working process alters the steel’s microstructure, leading to several key improvements:

- Enhanced Strength and Hardness: Cold rolling increases the yield strength and tensile strength of the steel, making it more resistant to deformation and breakage. This is due to the work hardening effect, where the steel’s crystalline structure becomes more tightly packed.

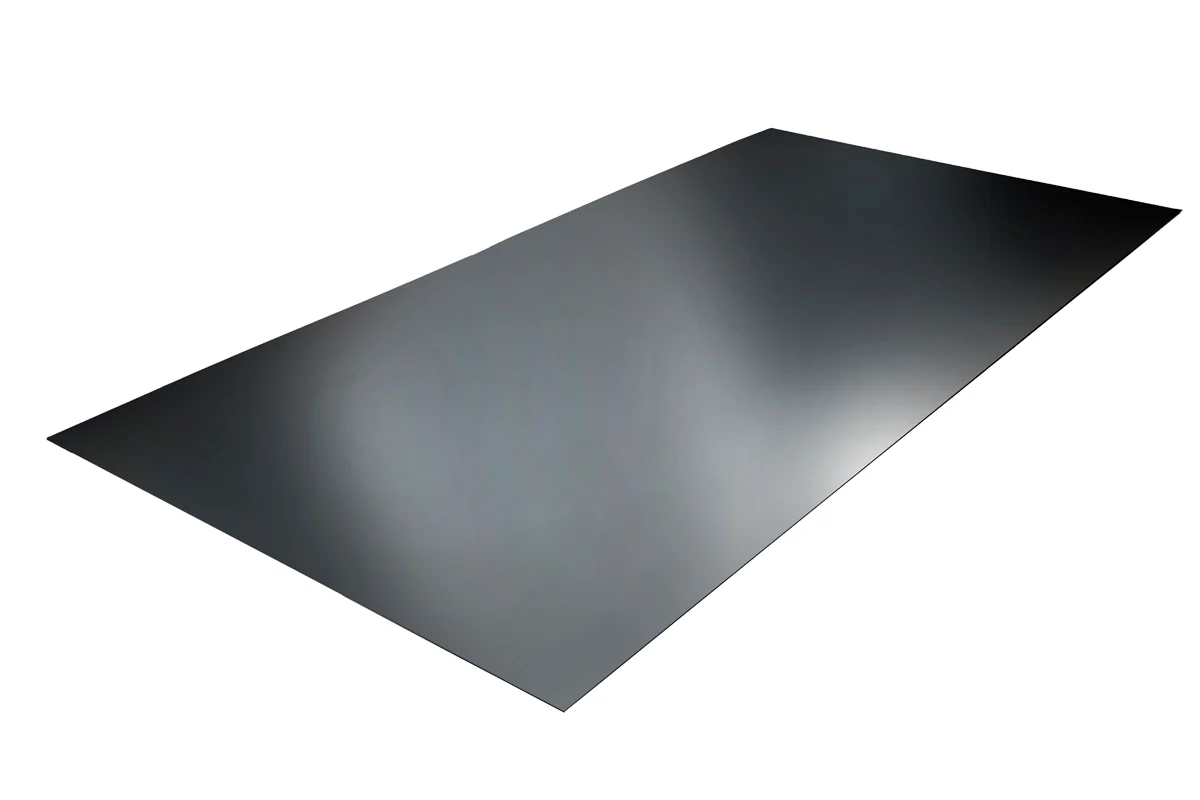

- Improved Surface Finish: The cold rolling process produces a smooth, clean surface, free from the scale and imperfections often found on hot rolled steel. This makes cold rolled sheets ideal for applications requiring a visually appealing finish.

- Tighter Dimensional Tolerances: The controlled environment and precise rolling equipment used in cold rolling result in sheets with significantly tighter dimensional tolerances compared to hot rolled steel. This precision is crucial for applications where accurate fit and alignment are essential.

- Greater Uniformity: Cold rolling provides a more consistent thickness throughout the sheet, leading to improved uniformity in the final product.

Advantages of Using Cold Rolled Sheets:

The benefits of using cold rolled sheets are numerous and directly impact the quality and performance of the final product:

- Superior Surface Finish: Ideal for applications requiring a smooth, paintable, or aesthetically pleasing surface.

- Dimensional Accuracy: Crucial for applications where precise fit and alignment are paramount.

- Increased Strength and Hardness: Enables the use of thinner gauges without sacrificing structural integrity.

- Improved Machinability: The smoother surface and tighter tolerances often improve machinability and reduce tool wear.

- Enhanced Formability: While generally less formable than hot rolled steel, specific cold rolling processes can improve formability for certain applications.

Applications of Cold Rolled Sheets:

The unique properties of cold rolled sheets make them suitable for a diverse range of applications across various industries:

- Automotive: Used in car bodies, panels, and structural components due to their strength, surface finish, and dimensional accuracy.

- Appliances: Found in refrigerators, washing machines, and other appliances where appearance and durability are important.

- Furniture: Used in metal furniture frames, cabinets, and decorative elements.

- Construction: Employed in roofing, siding, and other building components.

- Electronics: Used in computer cases, electronic enclosures, and other electronic equipment due to their precise dimensions and smooth surfaces.

- General Manufacturing: Used in a wide variety of manufactured goods, including shelving, filing cabinets, and industrial equipment.

Considerations When Choosing Cold Rolled Sheets:

While cold rolled sheets offer many advantages, it’s important to consider certain factors when selecting the right material for your application:

- Cost: Cold rolled sheets are generally more expensive than hot rolled sheets due to the additional processing involved.

- Formability: Cold rolling reduces formability compared to hot rolled steel. If complex forming is required, consider using specific cold rolling processes designed to improve formability.

- Corrosion Resistance: Cold rolled sheets are susceptible to corrosion and typically require a protective coating, such as paint, galvanizing, or powder coating.

Conclusion:

Cold rolled sheets are a versatile and valuable material for a wide range of applications. Their superior surface finish, tight tolerances, and enhanced strength make them an excellent choice for projects demanding precision, durability, and aesthetic appeal. By understanding the properties and limitations of cold rolled sheets, engineers and manufacturers can make informed decisions and create high-quality products that meet the demands of modern industries.

Reviews

There are no reviews yet.