Description

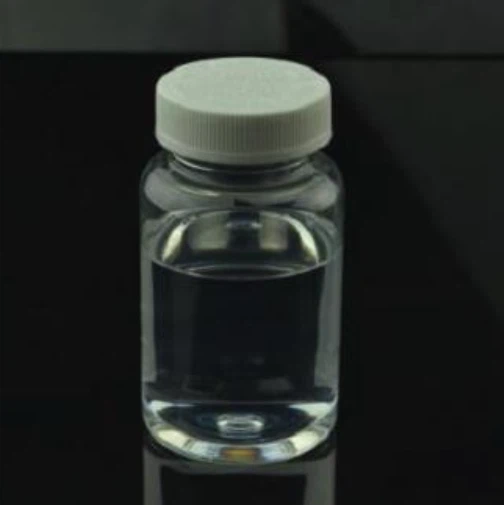

Isophorone diisocyanate (IPDI)

Isophorone diisocyanate (IPDI) is an aliphatic diisocyanate widely used in polyurethane (PU) chemistry. It is derived from isophorone and contains two reactive isocyanate (-NCO) groups that enable chain extension with polyols to form polyurethanes.

Key points

- Type: Aliphatic diisocyanate based on an isophorone-derived ring

- Reactivity: Two -NCO groups allow formation of polyurethane networks with polyols

- Isomer content: Usually supplied as a mixture of isomers; may be marketed as cis/trans or other isomeric forms depending on supplier

Structure and isomers

- IPDI features a cycloaliphatic skeleton with two isocyanate groups

- It is commonly available as technical grade mixtures containing several isomers

- Some grades offer purified cis or trans isomers, depending on the application needs

Properties (typical considerations)

- Weathering and color stability: Superior to aromatic diisocyanates, with better UV resistance and lower color formation

- Color: Generally low color formation, contributing to lighter PU products

- Processing: Suitable for coatings, elastomeric systems, and flexible foams; can be formulated with a range of polyols

- Storage: Handle as a reactive monomer, moisture sensitive; store in sealed containers away from moisture and heat

Common applications

- Coatings: Clear or pigmented polyurethane coatings with good outdoor durability

- Elastomeric systems: Flexible/moderate-hardness PU elastomers

- Adhesives and sealants: PU adhesives with good UV stability

- Foams: Flexible and semi-rlexible PU foams in specialty applications

Why choose IPDI over aromatic diisocyanates?

- Better UV and light stability, leading to longer-lasting, lighter-colored products

- More favorable color retention in outdoor or high-visibility coatings

- Lower potential for yellowing compared with aromatic diisocyanates like TDI or MDI

Safety and handling (high level)

- IPDI is a hazardous chemical; avoid inhalation, ingestion, and skin or eye contact

- Reacts with moisture to release CO2, so maintain dry handling conditions

- Use appropriate PPE (gloves, goggles, respirator if needed) and work in a well-ventilated area

- Store away from oxidizers and heat sources in properly labeled, sealed containers

- Follow the supplier’s Safety Data Sheet (SDS) for detailed handling, exposure limits, and first aid

Quick comparison with related diisocyanates

| Property | IPDI (aliphatic) | TDI (aromatic) | MDI (aromatic) |

|---|---|---|---|

| Weathering/UV stability | Excellent | Moderate to low | Moderate |

| Color stability | Very good | Prone to yellowing | Prone to color change |

| Odor | Usually milder | Stronger odor | Moderate to strong |

| Typical uses | Coatings, elastomers, specialty foams | Flexible foams, coatings, adhesives | Flexible and rigid foams, coatings |

| Reactivity with polyols | Good balance of reactivity and processing | Higher reactivity, faster cure | Balanced reactivity, widely used |

Summary

Isophorone diisocyanate is a versatile aliphatic diisocyanate favored for PU systems requiring good outdoor durability, light stability, and lighter color. It is available as mixtures of isomers and can be formulated to achieve a range of flexible to moderate-hard PU materials. As with all diisocyanates, proper safety practices are essential during handling and processing.

If you’d like, I can tailor this to a specific application (eg, a coating formulation or a particular polyol type) or provide a short comparison with a supplier’s IPDI grade.

Reviews

There are no reviews yet.