Description

Copper Chromite Catalyst: A Versatile Workhorse in Chemical Transformations

The realm of catalysis houses a diverse array of compounds, each tailored for specific chemical reactions. Among these, the Copper Chromite catalyst stands out as a versatile and historically significant player, known for its ability to facilitate various hydrogenation, dehydrogenation, and oxidation reactions. Despite facing competition from newer, more specialized catalysts, Copper Chromite continues to find application in both industrial processes and laboratory research, primarily due to its cost-effectiveness and robust nature.

What is Copper Chromite?

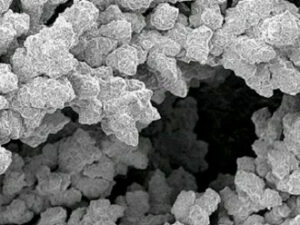

Copper Chromite, often represented as CuCr₂O₄, is a mixed metal oxide containing copper and chromium. However, the exact composition of commercially available Copper Chromite catalysts can vary, with additional components like barium, manganese, or zinc oxides often incorporated to improve performance and stability. These additives can influence the catalyst’s activity, selectivity, and resistance to poisoning.

A Historical Perspective

The development of Copper Chromite catalysts dates back to the early 20th century. Initially, its main application was the hydrogenation of esters to alcohols, a crucial step in the production of fatty alcohols used in detergents and other industrial products. Over time, its application broadened considerably, establishing its place as a workhorse catalyst in organic synthesis.

Key Applications and Reactions:

Copper Chromite’s versatility stems from its ability to catalyze a wide range of reactions, including:

- Hydrogenation: It efficiently catalyzes the hydrogenation of various functional groups, including esters, aldehydes, ketones, and nitro compounds. The reduction of esters to alcohols, as mentioned earlier, remains a significant application.

- Dehydrogenation: Under higher temperatures, Copper Chromite can also promote dehydrogenation reactions, such as the conversion of alcohols to aldehydes or ketones.

- Ammonolysis and Amination: It can be used in the ammonolysis of alcohols to produce amines and in the amination of carbonyl compounds.

- Water-Gas Shift Reaction (WGSR): Although not as efficient as copper-based catalysts supported on zinc oxide, Copper Chromite can still contribute to the Water-Gas Shift Reaction, a crucial process in hydrogen production.

- Oxidation: Copper Chromite can catalyze certain oxidation reactions, although its use in this area is less common due to the availability of more selective oxidation catalysts.

Advantages and Disadvantages:

Like any catalyst, Copper Chromite presents both advantages and disadvantages:

Advantages:

- Versatility: Its ability to catalyze a variety of reactions makes it suitable for different synthetic pathways.

- Cost-effectiveness: Compared to some noble metal catalysts (e.g., platinum, palladium), Copper Chromite is relatively inexpensive.

- Robustness: It can withstand relatively harsh reaction conditions, including high temperatures and pressures.

- Tolerance to Sulfur: Copper Chromite exhibits a degree of tolerance to sulfur-containing compounds, which can poison other catalysts.

Disadvantages:

- Lower Activity compared to noble metal catalysts: Often, it requires higher temperatures and pressures to achieve comparable conversion rates to noble metal catalysts.

- Selectivity Challenges: Achieving high selectivity can be challenging, as Copper Chromite can catalyze multiple reactions simultaneously.

- Toxicity Concerns: Chromium-containing compounds are often considered toxic, requiring careful handling and disposal.

- Surface Area Limitations: Copper Chromite typically has a lower surface area compared to supported catalysts, which can limit its activity.

Ongoing Research and Future Directions:

Despite its established history, research into Copper Chromite catalysts continues. Current efforts focus on:

- Improving Catalytic Activity: Researchers are exploring methods to enhance the catalyst’s surface area, tune its composition, and optimize its preparation methods.

- Enhancing Selectivity: Strategies are being developed to control the reaction pathway and improve the selectivity towards desired products. This includes modifying the catalyst with promoters and using specific reaction conditions.

- Addressing Toxicity Concerns: Exploration of alternative chromium-free catalysts with comparable performance is an ongoing area of research.

Conclusion:

The Copper Chromite catalyst remains a valuable tool in chemical synthesis and industrial processes. Its versatility, cost-effectiveness, and robustness make it a practical choice for a diverse range of reactions. While it faces competition from newer, more specialized catalysts, ongoing research and development efforts are focused on improving its performance and addressing concerns about toxicity, ensuring its continued relevance in the future of catalysis. Its historical significance and proven track record solidify its place as a valuable workhorse in the chemical industry.

Reviews

There are no reviews yet.