Description

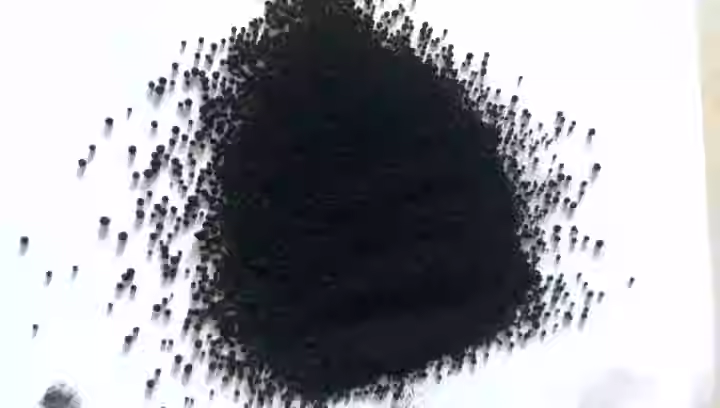

Acetylene Black: A Specialized Carbon Material with Unique Properties and Applications

Acetylene black, a specialized type of carbon black, stands apart from its more common counterparts due to its unique production process and the resulting exceptional purity and electrical conductivity. While carbon black is ubiquitous as a reinforcing agent in tires, acetylene black carves a niche for itself in applications where these specific properties are paramount.

Production Process: The Acetylene Difference

Unlike other carbon blacks produced by burning oil or natural gas, acetylene black is created through the thermal decomposition (pyrolysis) of acetylene gas (C₂H₂). This process, typically carried out at temperatures exceeding 800°C, results in a highly structured, relatively pure carbon material. The key characteristics differentiating acetylene black stem from this unique production method.

Key Characteristics and Properties:

- High Purity: The pyrolysis of acetylene produces a carbon material with minimal sulfur, ash, and other contaminants commonly found in other types of carbon black. This high purity is crucial for applications demanding minimal unwanted reactions or interference.

- Exceptional Electrical Conductivity: Acetylene black exhibits outstanding electrical conductivity due to its unique structure and purity. The interconnected chains and aggregates within the material provide numerous pathways for electron flow, making it a highly effective conductive filler.

- High Surface Area: The material possesses a relatively large surface area, contributing to its effective interaction with surrounding materials and enhancing its dispersion properties.

- Low Moisture and Volatile Content: Acetylene black typically exhibits low moisture and volatile content, making it suitable for applications requiring stability and minimal outgassing.

Applications Requiring Acetylene Black’s Specialized Properties:

These unique properties make acetylene black indispensable in a variety of specialized applications:

- Batteries: Arguably the most significant application is in lithium-ion batteries. Acetylene black acts as a conductive additive in the electrode material, enhancing electron transport and improving battery performance. It helps to increase charge/discharge rates, capacity, and overall lifespan.

- Capacitors: Similar to its role in batteries, acetylene black is used in capacitors to enhance conductivity and improve performance. Its high purity ensures minimal unwanted reactions within the sensitive capacitor environment.

- Conductive Plastics and Composites: Acetylene black is incorporated into plastics and composite materials to impart electrical conductivity. This allows for the creation of antistatic coatings, electromagnetic interference (EMI) shielding, and conductive adhesives.

- High-Performance Rubber Compounds: While common carbon black is the workhorse of tire reinforcement, acetylene black finds niche applications in specialty rubber compounds demanding higher conductivity or purity, such as conductive seals and gaskets.

- Electrode Materials: Beyond batteries, acetylene black is used in various electrode materials across different electrochemical applications, leveraging its conductivity and stability.

Advantages and Considerations:

The advantages of utilizing acetylene black are clear when its unique properties are crucial. It enables higher performance in applications like batteries and capacitors, provides excellent conductivity in plastics, and offers greater purity than other carbon black alternatives.

However, it’s also important to consider the following:

- Cost: Acetylene black is generally more expensive than other types of carbon black due to the specialized production process.

- Handling: As a fine powder, proper handling procedures are necessary to prevent dust exposure and ensure safe working conditions.

- Dispersion: While acetylene black boasts a high surface area, achieving uniform dispersion within the target matrix is essential to maximize its benefits.

Looking Ahead:

As energy storage technologies continue to evolve and demand for high-performance materials increases, the importance of acetylene black is likely to grow. Ongoing research is focused on optimizing its production process, enhancing its properties further, and expanding its applications in emerging fields like flexible electronics and advanced composites.

In conclusion, acetylene black is a specialized carbon material with unique properties driven by its distinct production process. While it’s not a universal replacement for common carbon blacks, its exceptional purity and electrical conductivity make it an indispensable ingredient in applications demanding superior performance and reliability. Its role in battery technology and other advanced materials positions it as a key component in the future of electronics and energy storage.

Reviews

There are no reviews yet.